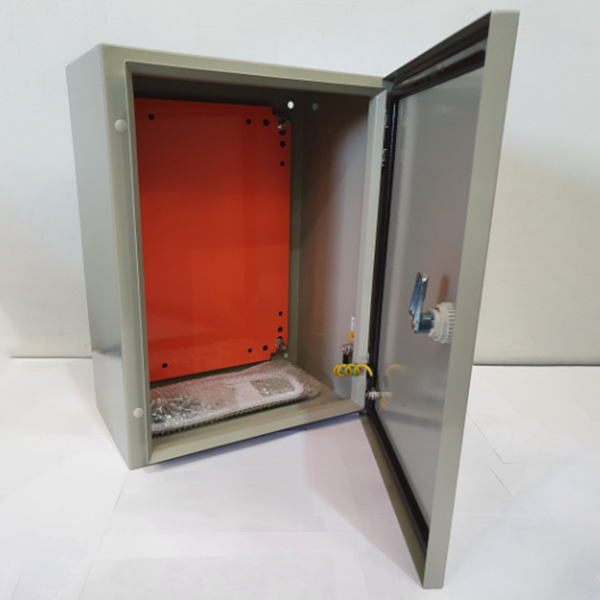

Weatherproof Outdoor Electrical Cabinet Enclosures

In outdoor environments, electrical equipment needs reliable protection to cope with various adverse weather conditions. Waterproof outdoor electrical cabinets are designed to meet this demand. These electrical cabinets are waterproof, dustproof, corrosion-resistant and high-temperature resistant, and can effectively protect the internal electrical equipment from the influence of the external environment.

First of all, waterproof outdoor electrical cabinets are made of high-quality materials, such as stainless steel or aluminum alloy, with excellent corrosion resistance, and can be used for a long time in humid or rainy environments without damage. Secondly, these cabinets are equipped with sealing rings with good sealing performance, which can effectively prevent rain, dust and other external substances from entering the box body to ensure the safe operation of electrical equipment. In addition, the surface of the cabinet has been specially treated with good high-temperature resistance, and can maintain stable operation in high-temperature environments, and will not cause equipment failure due to excessive ambient temperature.

In addition to basic protection functions, waterproof outdoor electrical cabinets also have certain intelligent designs. For example, some cabinets are equipped with temperature sensors and humidity sensors, which can monitor the temperature and humidity changes inside the box in real time, take corresponding measures in time, and ensure the safe operation of the equipment. In addition, some models of cabinets are also equipped with remote monitoring functions, and users can remotely monitor the working status of the cabinet through mobile phones or computers, and understand the operation of the equipment at any time.

In general, waterproof outdoor electrical cabinets are important protective devices for outdoor electrical equipment. They have the characteristics of being waterproof, dustproof, corrosion-resistant and high-temperature resistant. They can effectively protect electrical equipment from the influence of the external environment and ensure its safe and stable operation.

Sheet metal parts are found almost everywhere and Wongsam Sheet Metal Technology Co., Ltd ( Wongsam ) can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes. We have an ultra low MOQ (minimum order quantity) of one unit and offer lots of manufacturing options for low/mid volumes.

How It Works – Sheet metal encompasses a wide range of processes to manipulate and shape sheets of metal into the required form or geometry. Wongsam use bending, laser cutting, punches, welding and other processes to manufacture your sheet metal parts and prototypes.

Contact us today to find out more about our sheet metal production services.

Optional Materials

Brass, Aluminum, Stainless steel , and Zinc etc.

Customized Thickness

The thickness of sheet metal can be done as per client's request. Thickness: 0.6-60mm available

Low material waste

Can cost-effectively scale to production volumes

Multiple finishing options like anodizing and powder coating

Sheet Metal Applications

Sheet metal is a versatile manufacturing process for a range of metal components. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Common sheet metal parts include:

Sheet Metal Fabrication, Parts

Metal Cabinets, Box, Enclosure

Metal Racks, Shelves, Bracket

Metal Veneer, Panel, Facade

Car Shelf Bracket

Metal Chassis, Frame

Turned Parts

Appliances

Sheet Metal Finishing Options

Looking for more than a few basic sheet metal parts? We offer welding, hardware insertion, plating, silk screening, and powder coating to provide complete sheet metal components all under one roof.