Stereo Vertical Network Server Rack

In modern data centers and home audio systems, the management and organization of equipment is critical. For those looking for an efficient solution, Vertical Network Rack and Vertical Server Rack are ideal choices. These racks not only save space but also improve equipment accessibility and maintenance efficiency. For audio enthusiasts, Stereo Racks provide an ideal device management method.

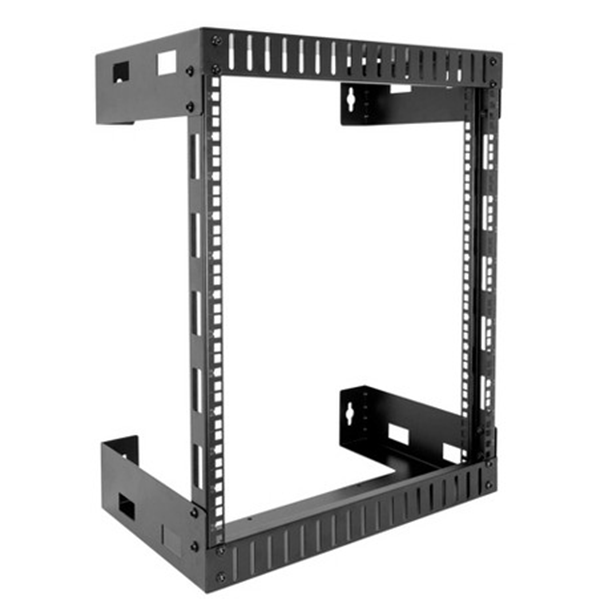

Vertical network server rack

Vertical network server racks are solutions specifically designed for vertical mounting of network equipment. These racks typically have a smaller footprint, making them ideal for environments with limited space. They can accommodate a variety of network equipment such as switches, routers, and servers, allowing for efficient space utilization.

Another significant advantage of these racks is their ease of management and maintenance. Because the equipment is mounted vertically, technicians can more easily access each device, simplifying equipment upgrades and maintenance. In addition, the vertical design also helps improve heat dissipation, ensuring that the device operates at an optimal temperature.

Vertical server rack

Tower server racks are similar to tower network racks, but they are designed specifically for servers. These racks are usually built ruggedly and can withstand heavier server equipment. Vertical server racks not only help save space but also provide efficient cooling solutions to ensure servers do not overheat when running at high performance.

These racks often come with slide rails and adjustable brackets, making server installation and removal easier. In addition, the vertical design also improves the serviceability of the equipment, making it easier for technicians to perform troubleshooting and maintenance.

Vertical audio stand

For audio enthusiasts, a vertical audio stand is an ideal way to manage your equipment. Stereo Racks are designed for storing and displaying audio equipment such as amplifiers, CD players and mixers. These racks typically feature multiple compartments and brackets that can be flexibly adjusted to accommodate different sized equipment.

The vertical audio stand not only enhances the aesthetics of the equipment, but also improves the ventilation and heat dissipation of the audio equipment. Audio equipment usually requires good cooling conditions to ensure that the sound quality is not affected during long-term operation. The vertical design can effectively improve the ventilation effect and extend the service life of the equipment.

Overall, vertical network server racks, vertical server racks, and vertical audio racks are all important tools for modern equipment management. They not only save space and improve device accessibility, but also effectively improve cooling conditions to ensure that the device operates at its best. So whether it's a data center or a home audio system, choosing the right vertical rack is a smart move.

Sheet metal parts are found almost everywhere and Wongsam Sheet Metal Technology Co., Ltd ( Wongsam ) can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes. We have an ultra low MOQ (minimum order quantity) of one unit and offer lots of manufacturing options for low/mid volumes.

How It Works – Sheet metal encompasses a wide range of processes to manipulate and shape sheets of metal into the required form or geometry. Wongsam use bending, laser cutting, punches, welding and other processes to manufacture your sheet metal parts and prototypes.

Contact us today to find out more about our sheet metal production services.

Optional Materials

Brass, Aluminum, Stainless steel , and Zinc etc.

Customized Thickness

The thickness of sheet metal can be done as per client's request. Thickness: 0.6-60mm available

Low material waste

Can cost-effectively scale to production volumes

Multiple finishing options like anodizing and powder coating

Sheet Metal Applications

Sheet metal is a versatile manufacturing process for a range of metal components. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Common sheet metal parts include:

Sheet Metal Fabrication, Parts

Metal Cabinets, Box, Enclosure

Metal Racks, Shelves, Bracket

Metal Veneer, Panel, Facade

Car Shelf Bracket

Metal Chassis, Frame

Turned Parts

Appliances

Sheet Metal Finishing Options

Looking for more than a few basic sheet metal parts? We offer welding, hardware insertion, plating, silk screening, and powder coating to provide complete sheet metal components all under one roof.