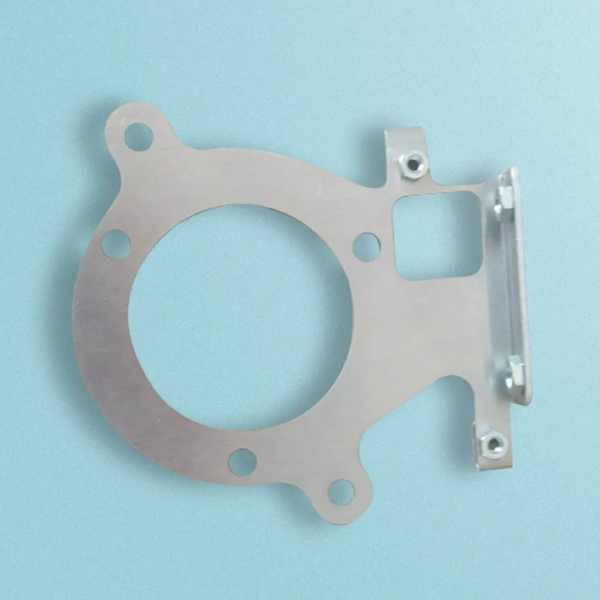

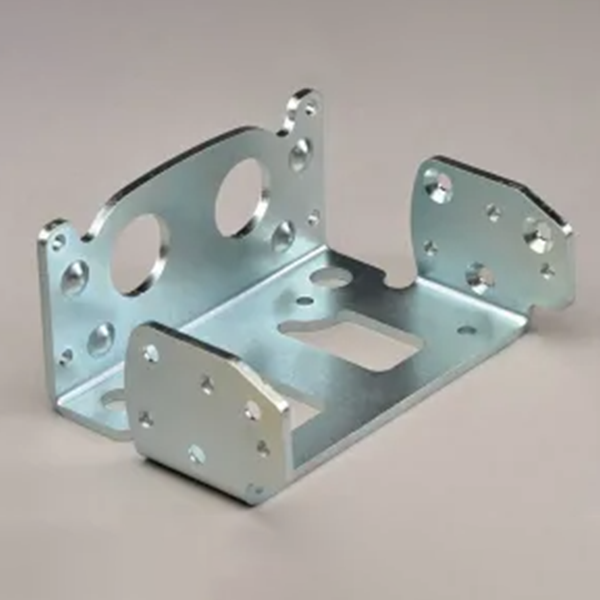

Sheet Metal Finishing Machining Manufacturing Service

In modern manufacturing, sheet metal machining services, sheet metal manufacturing, sheet metal finishing services (sheet metal machining services, sheet metal manufacturing, sheet metal finishing) play a vital role. These services not only improve the functionality and aesthetics of the product, but also significantly increase the product's service life and performance. This article will take a closer look at sheet metal fabrication services, sheet metal fabrication, and sheet metal surface treatment.

Sheet metal processing services

Definition and process

Sheet metal machining services refer to the use of various machining technologies to perform cutting, stamping, bending, welding and other process operations on metal sheets to manufacture the required metal parts. These services typically include technologies such as CNC cutting, laser cutting, CNC stamping, and CNC bending.

Application areas

Sheet metal processing is widely used in many industries such as electronics, electrical appliances, automobiles, aerospace, construction and furniture. For example, in the electronics industry, sheet metal processing is used to manufacture chassis, cabinets and various structural parts; in the automotive industry, it is used to produce body parts and spare parts.

Sheet metal manufacturing

manufacturing process

Sheet metal manufacturing refers to processing metal sheets into required finished parts through a series of processes. The process typically includes steps such as material selection, design, cutting, forming, welding and assembly. Modern sheet metal manufacturing technology relies on advanced CNC equipment and automated production lines to achieve high-precision and high-efficiency production.

Technical advantages

Sheet metal fabrication offers the following advantages:

High precision: CNC equipment ensures high precision in the machining process and is able to produce complex and precise metal parts.

High efficiency: Automated production lines and advanced processing technology significantly improve production efficiency and shorten the production cycle.

Flexibility: Sheet metal manufacturing can be customized according to the specific needs of customers to meet various personalized requirements.

Sheet metal surface treatment

importance

Sheet metal finishing refers to the surface treatment of processed metal parts to improve their aesthetics, corrosion resistance and service life. Common surface treatment processes include spraying, electroplating, anodizing and polishing.

Process type

Spray coating: By spraying a layer of protective paint on the metal surface, the anti-corrosion performance and aesthetics of the component are enhanced.

Electroplating: Using the principle of electrochemistry to plate a layer of metal or alloy on the metal surface to improve its wear resistance and corrosion resistance.

Anodizing: Mainly used for aluminum products, an oxide film is formed on the surface through electrochemical methods to improve corrosion resistance and hardness.

Polishing: Polishing metal surfaces by mechanical or chemical methods to obtain a smooth, flat and shiny surface.

Sheet metal processing, manufacturing and surface treatment services are an important part of modern manufacturing. Efficient sheet metal processing services and advanced manufacturing technology, combined with diverse surface treatment processes, can significantly improve product quality and performance. As technology continues to advance, these services will play a more important role in the future manufacturing industry and promote innovation and development in various industries.

Sheet metal parts are found almost everywhere and Wongsam Sheet Metal Technology Co., Ltd ( Wongsam ) can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes. We have an ultra low MOQ (minimum order quantity) of one unit and offer lots of manufacturing options for low/mid volumes.

How It Works – Sheet metal encompasses a wide range of processes to manipulate and shape sheets of metal into the required form or geometry. Wongsam use bending, laser cutting, punches, welding and other processes to manufacture your sheet metal parts and prototypes.

Contact us today to find out more about our sheet metal production services.

Optional Materials

Brass, Aluminum, Stainless steel , and Zinc etc.

Customized Thickness

The thickness of sheet metal can be done as per client's request. Thickness: 0.6-60mm available

Low material waste

Can cost-effectively scale to production volumes

Multiple finishing options like anodizing and powder coating

Sheet Metal Applications

Sheet metal is a versatile manufacturing process for a range of metal components. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Common sheet metal parts include:

Sheet Metal Fabrication, Parts

Metal Cabinets, Box, Enclosure

Metal Racks, Shelves, Bracket

Metal Veneer, Panel, Facade

Car Shelf Bracket

Metal Chassis, Frame

Turned Parts

Appliances

Sheet Metal Finishing Options

Looking for more than a few basic sheet metal parts? We offer welding, hardware insertion, plating, silk screening, and powder coating to provide complete sheet metal components all under one roof.