Quick Turn Rapid Sheet Metal Fabrication

In modern manufacturing, quick turn sheet metal fabrication has become a key technology that can produce high-quality sheet metal products in a short time. The application of this technology not only significantly improves production efficiency, but also meets customers' needs for rapid product iteration and market changes.

The definition of rapid sheet metal processing

Rapid sheet metal processing refers to quickly processing metal sheets into the required shape and structure through a series of efficient processes, such as laser cutting, CNC stamping, bending and welding. This process usually includes design, prototyping, production and quality inspection, and can be completed within days or even hours.

Technical features and advantages

Efficient production

Rapid sheet metal processing utilizes advanced CNC technology and automation equipment to significantly reduce processing time and labor costs. This technology enables the production of metal products with greater precision and complexity in less time than traditional sheet metal processing methods.

flexibility

Rapid sheet metal processing is extremely flexible and can be customized to meet the specific needs of customers. This is of great significance for companies that need to respond quickly to market changes and customer needs. For example, during the new product development stage, companies can quickly produce multiple prototypes of different designs for testing and optimization through rapid sheet metal processing.

Excellent product quality

Rapid sheet metal processing is not only fast, but also ensures high quality of products. Through precision CNC equipment and strict quality control processes, the sheet metal products produced have high precision, high strength and good surface treatment effects, and can meet various high-standard industrial needs.

Application areas

Electronics and electrical appliances industry

In the electronics and electrical appliances industry, rapid sheet metal processing is widely used in the production of chassis, cabinets and various structural parts. Since this industry has high requirements for product update speed, rapid sheet metal processing can meet market demand in a timely manner and improve the competitiveness of enterprises.

Automotive Manufacturing

Automotive manufacturing is another important application area. Rapid sheet metal processing technology can quickly produce prototypes and small batch production parts of body parts during the development stage of new models, providing strong support for vehicle design and performance optimization.

furniture manufacturing

In the furniture manufacturing industry, rapid sheet metal processing also plays an important role. Modern furniture design has increasingly higher requirements for aesthetics and functionality. Through rapid sheet metal processing, various innovatively designed furniture components can be quickly produced to meet consumers' needs for personalized and high-quality furniture.

In short, rapid sheet metal processing is an important technology in modern manufacturing. With its high efficiency, flexibility and high quality, it is widely used in electronics, electrical appliances, automobiles, furniture and other industries. With the continuous development of technology, rapid sheet metal processing will play a more important role in the future, promoting innovation and development in various industries.

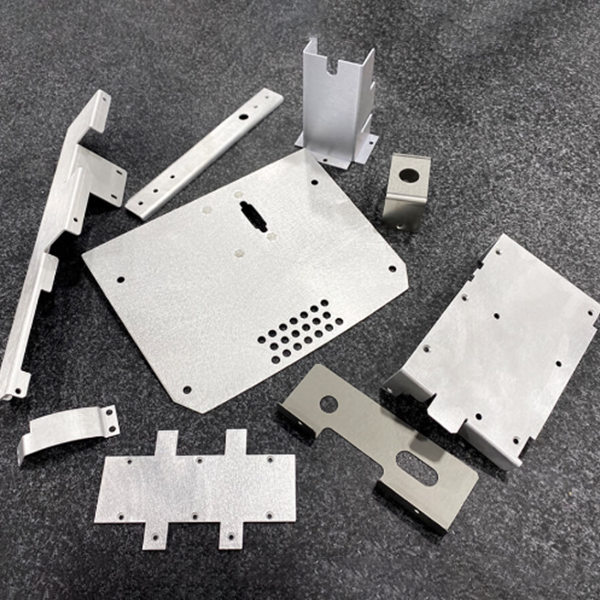

Sheet metal parts are found almost everywhere and Wongsam Sheet Metal Technology Co., Ltd ( Wongsam ) can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes. We have an ultra low MOQ (minimum order quantity) of one unit and offer lots of manufacturing options for low/mid volumes.

How It Works – Sheet metal encompasses a wide range of processes to manipulate and shape sheets of metal into the required form or geometry. Wongsam use bending, laser cutting, punches, welding and other processes to manufacture your sheet metal parts and prototypes.

Contact us today to find out more about our sheet metal production services.

Optional Materials

Brass, Aluminum, Stainless steel , and Zinc etc.

Customized Thickness

The thickness of sheet metal can be done as per client's request. Thickness: 0.6-60mm available

Low material waste

Can cost-effectively scale to production volumes

Multiple finishing options like anodizing and powder coating

Sheet Metal Applications

Sheet metal is a versatile manufacturing process for a range of metal components. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Common sheet metal parts include:

Sheet Metal Fabrication, Parts

Metal Cabinets, Box, Enclosure

Metal Racks, Shelves, Bracket

Metal Veneer, Panel, Facade

Car Shelf Bracket

Metal Chassis, Frame

Turned Parts

Appliances

Sheet Metal Finishing Options

Looking for more than a few basic sheet metal parts? We offer welding, hardware insertion, plating, silk screening, and powder coating to provide complete sheet metal components all under one roof.