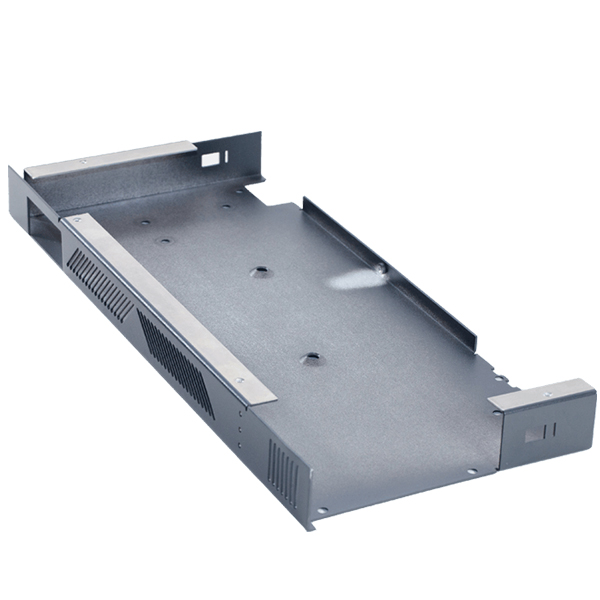

Prototype Sheet Metal Prototyping Fabrication

Prototype sheet metal prototyping plays an important role in modern manufacturing. Sheet metal prototyping is a method of using metal sheets to produce metal prototypes in the design stage through processes such as cutting, bending and forming. This process can not only effectively verify the feasibility of the design, but also discover potential problems and make timely modifications.

Prototype metal fabrication involves a variety of technologies and processes, such as laser cutting, stamping, welding and bending. Through these processes, metal sheets can be processed into various complex shapes and structures to meet the needs of different products. Metal prototyping not only improves the efficiency of product development, but also reduces development costs.

Prototype sheet metal fabrication is widely used in industries such as automobiles, aerospace, electronics and home appliances. It not only helps engineers and designers to quickly verify and optimize designs, but also conducts small-batch trial production before mass production of products to ensure that product quality and performance meet expected standards.

In short, prototype sheet metal prototyping is a key link in the product development process, with significant advantages of shortening development cycles, reducing costs and improving product quality. As technology continues to advance, this field will provide more efficient and flexible solutions for all industries.

Sheet metal parts are found almost everywhere and Wongsam can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes. We have an ultra low MOQ (minimum order quantity) of one unit and offer lots of manufacturing options for low/mid volumes.

How It Works – Sheet metal encompasses a wide range of processes to manipulate and shape sheets of metal into the required form or geometry. Wongsam use bending, laser cutting, punches, welding and other processes to manufacture your sheet metal parts and prototypes.

Contact us today to find out more about our sheet metal production services.

Optional Materials

Brass, Aluminum, Stainless steel , and Zinc etc.

Customized Thickness

The thickness of sheet metal can be done as per client's request. Thickness: 0.6-60mm available

Low material waste

Can cost-effectively scale to production volumes

Multiple finishing options like anodizing and powder coating

Sheet Metal Applications

Sheet metal is a versatile manufacturing process for a range of metal components. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Common sheet metal parts include:

Sheet Metal Fabrication, Parts

Metal Cabinets, Box, Enclosure

Metal Racks, Shelves, Bracket

Metal Veneer, Panel, Facade

Car Shelf Bracket

Metal Chassis, Frame

Turned Parts

Appliances

Sheet Metal Finishing Options

Looking for more than a few basic sheet metal parts? We offer welding, hardware insertion, plating, silk screening, and powder coating to provide complete sheet metal components all under one roof.