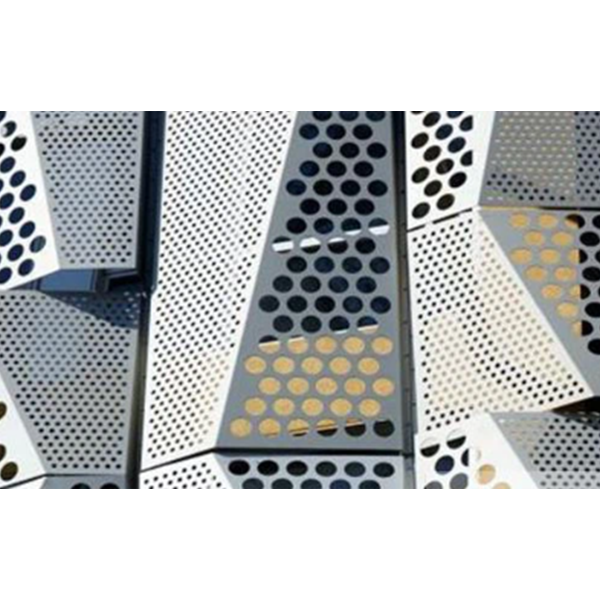

Perforated Metal Panels Facade

In architectural design, perforated metal facades are an eye-catching design element that not only adds a unique look to a building, but also brings a unique light and shadow effect to the interior space. Perforated metal sheets are usually made of metal materials and are named by creating holes of various sizes and shapes on the surface.

These metal sheets are widely used in building facades to form perforated metal facades. This kind of facade not only has a beautiful appearance, but also has multiple functions. First, perforated metal sheets can effectively control natural light and heat inside the building, making the indoor environment more comfortable. Second, they can provide a certain degree of privacy protection while maintaining ventilation and visual connection.

The design of perforated metal facades is also very flexible and can be customized according to the overall style and needs of the building. Designers can choose holes of different shapes, sizes and arrangements to create unique patterns and effects. Some designs even design holes into artworks or building logos, enhancing the recognition and visual appeal of the building.

In addition to the advantages in appearance, perforated metal facades are also durable and easy to maintain. Metal materials are generally able to withstand harsh weather conditions and environmental impacts and are not easily corroded or damaged. In addition, cleaning and maintenance are relatively simple, and only regular cleaning of the surface is required to keep it in good condition.

In general, perforated metal facades, as an architectural design element, not only provide beauty and functionality, but also show innovative and modern design concepts. In future architectural designs, they will continue to play an important role and bring more surprises and inspiration to the architectural world.

Sheet metal parts are found almost everywhere and Wongsam Sheet Metal Technology Co., Ltd ( Wongsam ) can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes. We have an ultra low MOQ (minimum order quantity) of one unit and offer lots of manufacturing options for low/mid volumes.

How It Works – Sheet metal encompasses a wide range of processes to manipulate and shape sheets of metal into the required form or geometry. Wongsam use bending, laser cutting, punches, welding and other processes to manufacture your sheet metal parts and prototypes.

Contact us today to find out more about our sheet metal production services.

Optional Materials

Brass, Aluminum, Stainless steel , and Zinc etc.

Customized Thickness

The thickness of sheet metal can be done as per client's request. Thickness: 0.6-60mm available

Low material waste

Can cost-effectively scale to production volumes

Multiple finishing options like anodizing and powder coating

Sheet Metal Applications

Sheet metal is a versatile manufacturing process for a range of metal components. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Common sheet metal parts include:

Sheet Metal Fabrication, Parts

Metal Cabinets, Box, Enclosure

Metal Racks, Shelves, Bracket

Metal Veneer, Panel, Facade

Car Shelf Bracket

Metal Chassis, Frame

Turned Parts

Appliances