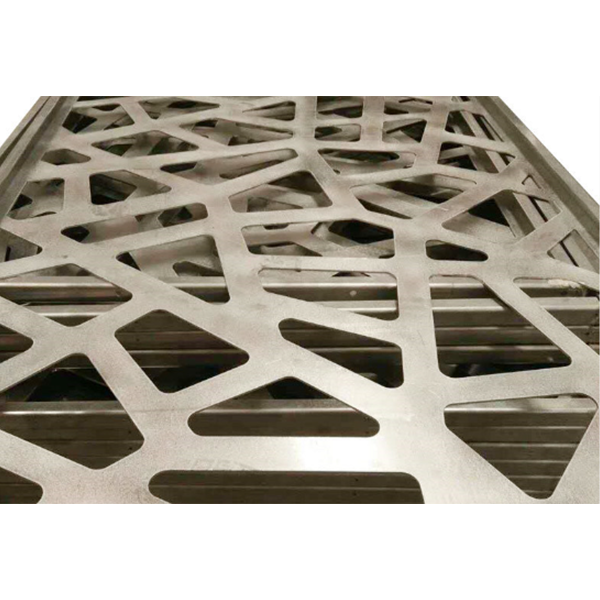

Perforated Metal Facade Pattern

Metal curtain walls have always been an important element in architectural design. They not only provide the beauty of the building's exterior, but also have the function of regulating indoor light and air. The perforated metal curtain wall is a special form of metal curtain wall. By perforating the metal plate, different patterns and textures are created, making it more artistic and personalized in appearance.

The design of perforated metal curtain wall patterns can be very diverse and can be customized according to the overall style of the building, environmental characteristics and functional requirements. This customized design allows each building to have a unique appearance and stand out from the crowd.

These patterns can be simple geometric shapes such as circles, squares or diamonds, or complex patterns such as plant textures, abstract patterns, etc. The selection and design of these patterns need to take into account the overall effect of the metal curtain wall and the needs of indoor light and vision to ensure that it is beautiful while still maintaining good functionality.

The choice of perforated metal curtain wall patterns can also be adjusted according to different seasons and times to adapt to different climatic conditions and lighting conditions. For example, a denser pattern can be selected in summer to block direct sunlight and reduce indoor heat, while a sparser pattern can be selected in winter to increase indoor lighting and warmth.

In addition to its decorative effect on the exterior, the perforated metal curtain wall can also adjust the indoor light and air through holes of different sizes and densities. This subtle adjustment can effectively improve the indoor environment and enhance the comfort of living and working.

Sheet metal parts are found almost everywhere and Wongsam Sheet Metal Technology Co., Ltd ( Wongsam ) can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes. We have an ultra low MOQ (minimum order quantity) of one unit and offer lots of manufacturing options for low/mid volumes.

How It Works – Sheet metal encompasses a wide range of processes to manipulate and shape sheets of metal into the required form or geometry. Wongsam use bending, laser cutting, punches, welding and other processes to manufacture your sheet metal parts and prototypes.

Contact us today to find out more about our sheet metal production services.

Optional Materials

Brass, Aluminum, Stainless steel , and Zinc etc.

Customized Thickness

The thickness of sheet metal can be done as per client's request. Thickness: 0.6-60mm available

Low material waste

Can cost-effectively scale to production volumes

Multiple finishing options like anodizing and powder coating

Sheet Metal Applications

Sheet metal is a versatile manufacturing process for a range of metal components. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Common sheet metal parts include:

Sheet Metal Fabrication, Parts

Metal Cabinets, Box, Enclosure

Metal Racks, Shelves, Bracket

Metal Veneer, Panel, Facade

Car Shelf Bracket

Metal Chassis, Frame

Turned Parts

Appliances