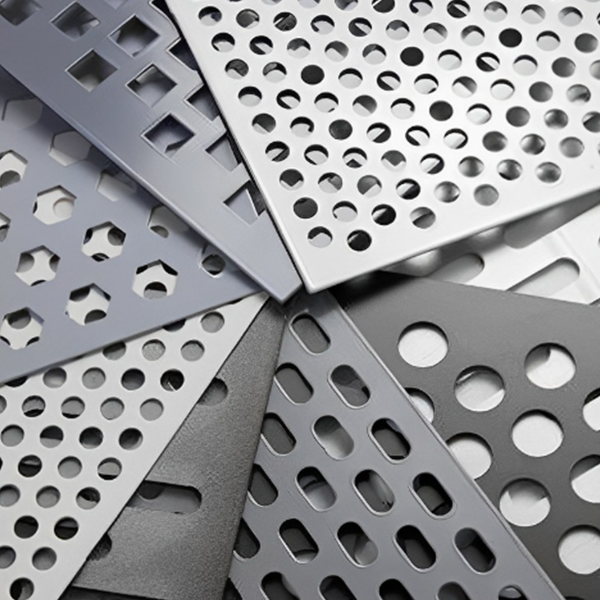

Pattern Architecture Perforated Metal Sheet

Perforated metal is a common building material. Its unique structure and function make it play an important role in architectural design. As a processed metal plate, it can achieve different functions and aesthetic effects by punching holes or cutting specific patterns on the surface. In the field of architecture, perforated metal plates are often used in exterior walls, ceilings, partitions and other parts. Its diverse pattern design and superior performance give buildings unique charm and functions.

First of all, perforated metal plates play a decorative and beautifying role in architectural design. Through carefully designed patterns and arrangements, perforated metal plates can give buildings a unique appearance, increase the artistic sense and visual appeal of buildings. Whether it is traditional geometric patterns or modern abstract patterns, they can be achieved through perforated metal plates, injecting vitality and vitality into buildings.

Secondly, perforated metal plates also have the function of adjusting light and ventilation in architectural design. Through holes of different sizes and shapes, perforated metal plates can control the entry of sunlight and the circulation of air, creating a comfortable environment indoors. Especially in hot climates, the application of perforated metal plates can effectively reduce indoor temperatures and improve the energy efficiency performance of buildings.

In addition, perforated metal plates can also be used to create private spaces and privacy protection. Through the reasonable design of hole density and arrangement, perforated metal sheets can effectively block sight while ensuring ventilation and light, providing a safe and private space for residents. This is especially important in public places or office spaces, which can effectively balance the needs of openness and privacy.

In general, perforated metal sheets, as a versatile building material, play an important role in modern architectural design. Its unique pattern design, light and ventilation adjustment functions, and privacy protection effect make it one of the first choices for architects. In the future, with the advancement of technology and the continuous innovation of design concepts, perforated metal sheets will surely show a broader application prospect in the field of architecture.

Sheet metal parts are found almost everywhere and Wongsam Sheet Metal Technology Co., Ltd ( Wongsam ) can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes. We have an ultra low MOQ (minimum order quantity) of one unit and offer lots of manufacturing options for low/mid volumes.

How It Works – Sheet metal encompasses a wide range of processes to manipulate and shape sheets of metal into the required form or geometry. Wongsam use bending, laser cutting, punches, welding and other processes to manufacture your sheet metal parts and prototypes.

Contact us today to find out more about our sheet metal production services.

Optional Materials

Brass, Aluminum, Stainless steel , and Zinc etc.

Customized Thickness

The thickness of sheet metal can be done as per client's request. Thickness: 0.6-60mm available

Low material waste

Can cost-effectively scale to production volumes

Multiple finishing options like anodizing and powder coating

Sheet Metal Applications

Sheet metal is a versatile manufacturing process for a range of metal components. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Common sheet metal parts include:

Sheet Metal Fabrication, Parts

Metal Cabinets, Box, Enclosure

Metal Racks, Shelves, Bracket

Metal Veneer, Panel, Facade

Car Shelf Bracket

Metal Chassis, Frame

Turned Parts

Appliances