Pallet Rack Protectors

Pallet rack protectors are important equipment used to protect warehouse pallet rack systems. They are mainly used to prevent forklifts, carts or other mechanical equipment from hitting and damaging rack columns and beams during operation. With the rapid development of the warehousing and logistics industries, pallet rack protectors have played a vital role in improving warehouse safety and extending the service life of racks.

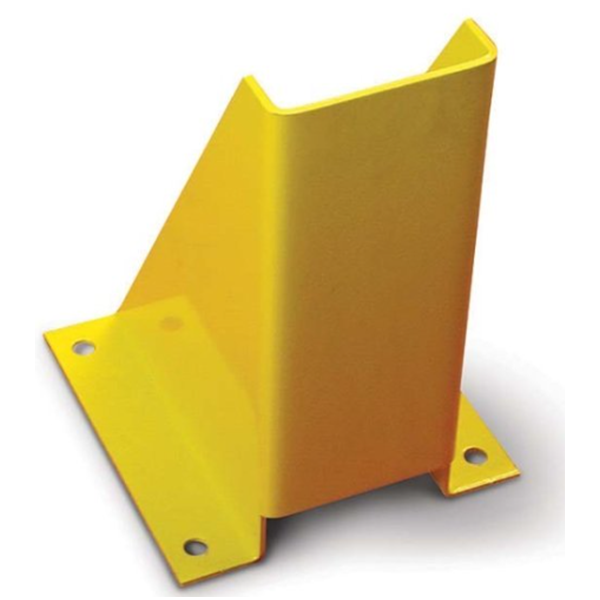

First of all, the main types of pallet rack protectors include column protectors, corner protectors and beam protectors. Column protectors are usually installed on the vertical pillars of the rack to prevent forklifts from accidentally hitting the pillars when moving pallets. Corner protectors are installed at the corners of the rack to provide more comprehensive protection and prevent the corners of the rack from being hit. Beam protectors are mainly used to protect the rack beams to prevent the beams from bending or breaking due to external impact.

Secondly, pallet rack protectors are made of a variety of materials, including steel, plastic and rubber. Steel protectors are sturdy and durable, suitable for heavy warehouse environments, while plastic and rubber protectors are more flexible and suitable for medium and light warehouses. They can effectively absorb impact and reduce direct damage to the racks.

The installation of pallet rack protectors is very important. Correct installation can not only protect the shelves to the greatest extent, but also improve the overall safety of the warehouse. During installation, it is necessary to ensure that the protector fits tightly to the shelf, and select the appropriate type of protector according to the specific structure of the shelf. In addition, regular inspection and maintenance of the protector is also essential to ensure that it is always in the best condition and plays its due protective role.

The use of pallet rack protectors can not only reduce the damage to warehouse facilities, but also improve the efficiency of warehouse operations. Avoiding downtime and repair time caused by shelf damage ensures the continuity and stability of warehousing operations. At the same time, reducing shelf damage also means reducing maintenance and replacement costs, thereby achieving higher economic benefits.

In short, pallet rack protectors, as an important part of warehouse safety management, have significant practical value. They can not only effectively prevent damage to the shelf system and extend its service life, but also improve the operational safety and efficiency of the warehouse. In modern warehousing and logistics management, pallet rack protectors have become indispensable equipment, which deserves the attention and adoption of every warehouse manager.

Sheet metal parts are found almost everywhere and Wongsam Sheet Metal Technology Co., Ltd ( Wongsam ) can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes. We have an ultra low MOQ (minimum order quantity) of one unit and offer lots of manufacturing options for low/mid volumes.

How It Works – Sheet metal encompasses a wide range of processes to manipulate and shape sheets of metal into the required form or geometry. Wongsam use bending, laser cutting, punches, welding and other processes to manufacture your sheet metal parts and prototypes.

Contact us today to find out more about our sheet metal production services.

Optional Materials

Brass, Aluminum, Stainless steel , and Zinc etc.

Customized Thickness

The thickness of sheet metal can be done as per client's request. Thickness: 0.6-60mm available

Low material waste

Can cost-effectively scale to production volumes

Multiple finishing options like anodizing and powder coating

Sheet Metal Applications

Sheet metal is a versatile manufacturing process for a range of metal components. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Common sheet metal parts include:

Sheet Metal Fabrication, Parts

Metal Cabinets, Box, Enclosure

Metal Racks, Shelves, Bracket

Metal Veneer, Panel, Facade

Car Shelf Bracket

Metal Chassis, Frame

Turned Parts

Appliances

Sheet Metal Finishing Options

Looking for more than a few basi