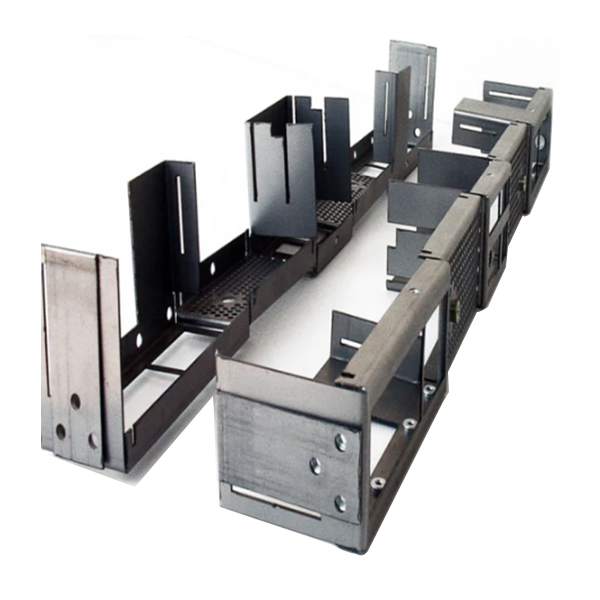

Heavy Sheet Metal Chassis

In the field of modern industry and mechanical manufacturing, heavy sheet metal chassis plays a vital role. Metal chassis and sheet metal chassis are the backbone of many devices and machines, providing the necessary structural support and protection.

Definition and Importance of Metal Chassis

A metal chassis is a shell or frame made of various metal materials, usually used to house and protect electronic equipment, mechanical components and other internal systems. Its main functions include providing structural support, preventing damage to internal components from the external environment, and heat dissipation. The material selection of metal chassis usually includes steel, aluminum and stainless steel, which are widely used for their strength, durability and thermal conductivity.

Manufacturing process of sheet metal chassis

Sheet metal chassis is a type of metal chassis that is manufactured using sheet metal technology. Sheet metal technology includes steps such as cutting, bending, stamping and welding to process metal sheets into the desired shape and size. This process requires high-precision equipment and technology to ensure the quality and consistency of the final product. Sheet metal chassis are favored by various industries because of their strong customizability and wide adaptability.

Application of Heavy Metal Chassis

Heavy Metal Chassis is designed for high load and high strength applications and is widely used in industries such as industry, military, aerospace, and heavy machinery. These chassis need to withstand extreme environmental conditions such as high temperature, high humidity, strong vibration, and heavy pressure. Therefore, heavy metal chassis usually use thicker metal materials and consider additional structural reinforcement in the design.

Advantages of Heavy Metal Chassis

Heavy metal chassis has the following significant advantages:

High strength and durability: Due to the use of high-strength metal materials, heavy metal chassis can be used for a long time under harsh working conditions without deformation or damage.

Protection performance: Heavy metal chassis can effectively prevent dust, moisture and other external factors from invading internal components.

Thermal management: The good thermal conductivity of metal materials helps the heat dissipation of equipment and ensures that the internal system operates within a safe temperature range.

Customization: According to specific needs, heavy metal chassis can be specially designed and processed to meet the requirements of different application scenarios.

Specific case analysis

In the field of industrial automation, heavy metal chassis are widely used in robot control cabinets and automated production line equipment. These chassis not only need to protect the complex electronic systems inside, but also need to provide good heat dissipation and shock resistance to ensure the stable operation of the equipment in high-intensity working environments. In military applications, heavy metal chassis are used as housings for communication equipment and radar systems, requiring extremely high impact resistance and protection to cope with harsh battlefield environments.

In summary, as an important part of modern industry, heavy metal chassis are widely used and vital in various fields. Through continuous technological innovation and material improvement, heavy metal chassis will continue to play a key role in industrial development.

Sheet metal parts are found almost everywhere and Wongsam Sheet Metal Technology Co., Ltd ( Wongsam ) can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes. We have an ultra low MOQ (minimum order quantity) of one unit and offer lots of manufacturing options for low/mid volumes.

How It Works – Sheet metal encompasses a wide range of processes to manipulate and shape sheets of metal into the required form or geometry. Wongsam use bending, laser cutting, punches, welding and other processes to manufacture your sheet metal parts and prototypes.

Contact us today to find out more about our sheet metal production services.

Optional Materials

Brass, Aluminum, Stainless steel , and Zinc etc.

Customized Thickness

The thickness of sheet metal can be done as per client's request. Thickness: 0.6-60mm available

Low material waste

Can cost-effectively scale to production volumes

Multiple finishing options like anodizing and powder coating

Sheet Metal Applications

Sheet metal is a versatile manufacturing process for a range of metal components. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Common sheet metal parts include:

Sheet Metal Fabrication, Parts

Metal Cabinets, Box, Enclosure

Metal Racks, Shelves, Bracket

Metal Veneer, Panel, Facade

Car Shelf Bracket

Metal Chassis, Frame

Turned Parts

Appliances

Sheet Metal Finishing Options

Looking for more than a few basic sheet metal parts? We offer welding, hardware insertion, plating, silk screening, and powder coating to provide complete sheet metal components all under one roof.