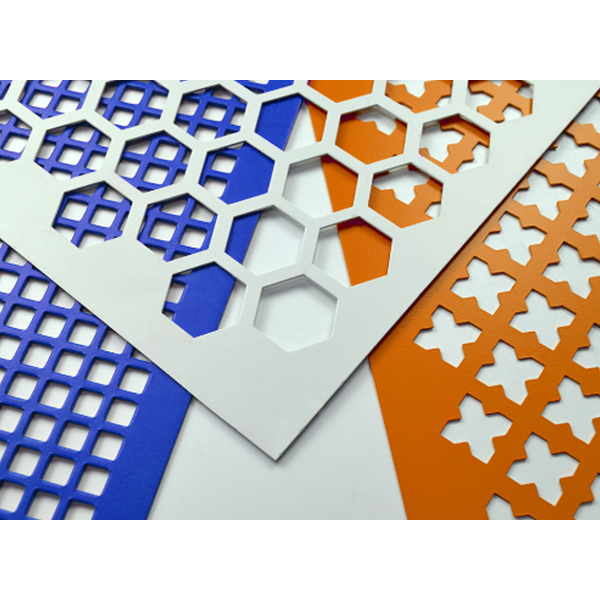

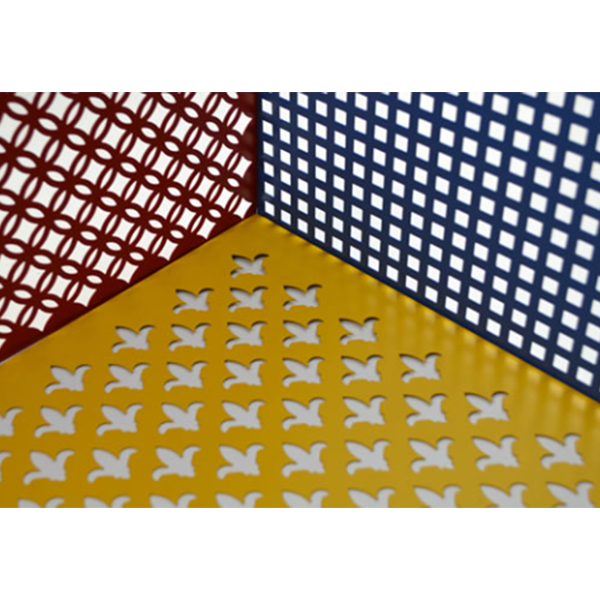

Decorative Stainless Steel Perforated Metal Sheet

Decorative perforated metal panels are a common material used in architecture and interior design and offer significant aesthetic and functional advantages. Stainless steel decorative perforated metal plates have unique charm and advantages in this regard.

Stainless steel perforated metal panels are typically made from high-quality stainless steel materials that are resistant to corrosion, abrasion, and high temperatures, allowing them to maintain long-lasting beauty and functionality when used outdoors or in humid environments. They are precision processed, with smooth and flat surfaces and good gloss, giving them a high-end and atmospheric feel.

This decorative perforated metal panel not only serves a decorative purpose, but also provides flexible partitioning and soundproofing in interior spaces. By designing holes of different shapes, sizes and densities in the metal plates, different levels of light transmission and ventilation can be achieved while ensuring privacy and visual effects.

Stainless steel decorative perforated metal panels have a wide range of applications and can be used in building exterior walls, indoor partitions, ceilings, railings, doors and windows, etc. Its design can be personalized according to actual needs to meet the decorative and functional requirements of different scenes.

In general, decorative stainless steel perforated metal panels not only have good decorative effects, but also have excellent durability and functionality. They are one of the indispensable and important materials in modern architecture and interior design.

Sheet metal parts are found almost everywhere and Wongsam Sheet Metal Technology Co., Ltd ( Wongsam ) can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes. We have an ultra low MOQ (minimum order quantity) of one unit and offer lots of manufacturing options for low/mid volumes.

How It Works – Sheet metal encompasses a wide range of processes to manipulate and shape sheets of metal into the required form or geometry. Wongsam use bending, laser cutting, punches, welding and other processes to manufacture your sheet metal parts and prototypes.

Contact us today to find out more about our sheet metal production services.

Optional Materials

Brass, Aluminum, Stainless steel , and Zinc etc.

Customized Thickness

The thickness of sheet metal can be done as per client's request. Thickness: 0.6-60mm available

Low material waste

Can cost-effectively scale to production volumes

Multiple finishing options like anodizing and powder coating

Sheet Metal Applications

Sheet metal is a versatile manufacturing process for a range of metal components. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Common sheet metal parts include:

Sheet Metal Fabrication, Parts

Metal Cabinets, Box, Enclosure

Metal Racks, Shelves, Bracket

Metal Veneer, Panel, Facade

Car Shelf Bracket

Metal Chassis, Frame

Turned Parts

Appliances