In the ever-evolving landscape of industrial manufacturing, sheet metal fabrication stands as a cornerstone of innovation, enabling the production of robust, precise components for diverse sectors. From supplying durable metal chassis to crafting specialized car shelf brackets, the industry has witnessed a surge in demand for high-quality, cost-effective solutions. This article delves into how sheet metal fabrication, led by advanced metal chassis factories, is reshaping supply chains and meeting global needs for products like low cost jumbo chassis and custom automotive components.supply metal chassissupply metal chassissupply metal chassissupply metal chassissupply metal chassissupply metal chassissupply metal chassissupply metal chassismetal chassis factorymetal chassis factorymetal chassis factorymetal chassis factorymetal chassis factorymetal chassis factory

Sheet metal fabrication is a versatile process that transforms flat metal sheets into complex structures through cutting, bending, and assembling. For industries seeking to supply metal chassis or buy jumbo chassis, the process offers unparalleled advantages:metal chassis factorymetal chassis factorymetal chassis factorymetal chassis factorymetal chassis factorylow cost jumbo chassislow cost jumbo chassislow cost jumbo chassiscar shelf bracketcar shelf bracketcar shelf bracketcar shelf bracketcar shelf bracketcar shelf bracket

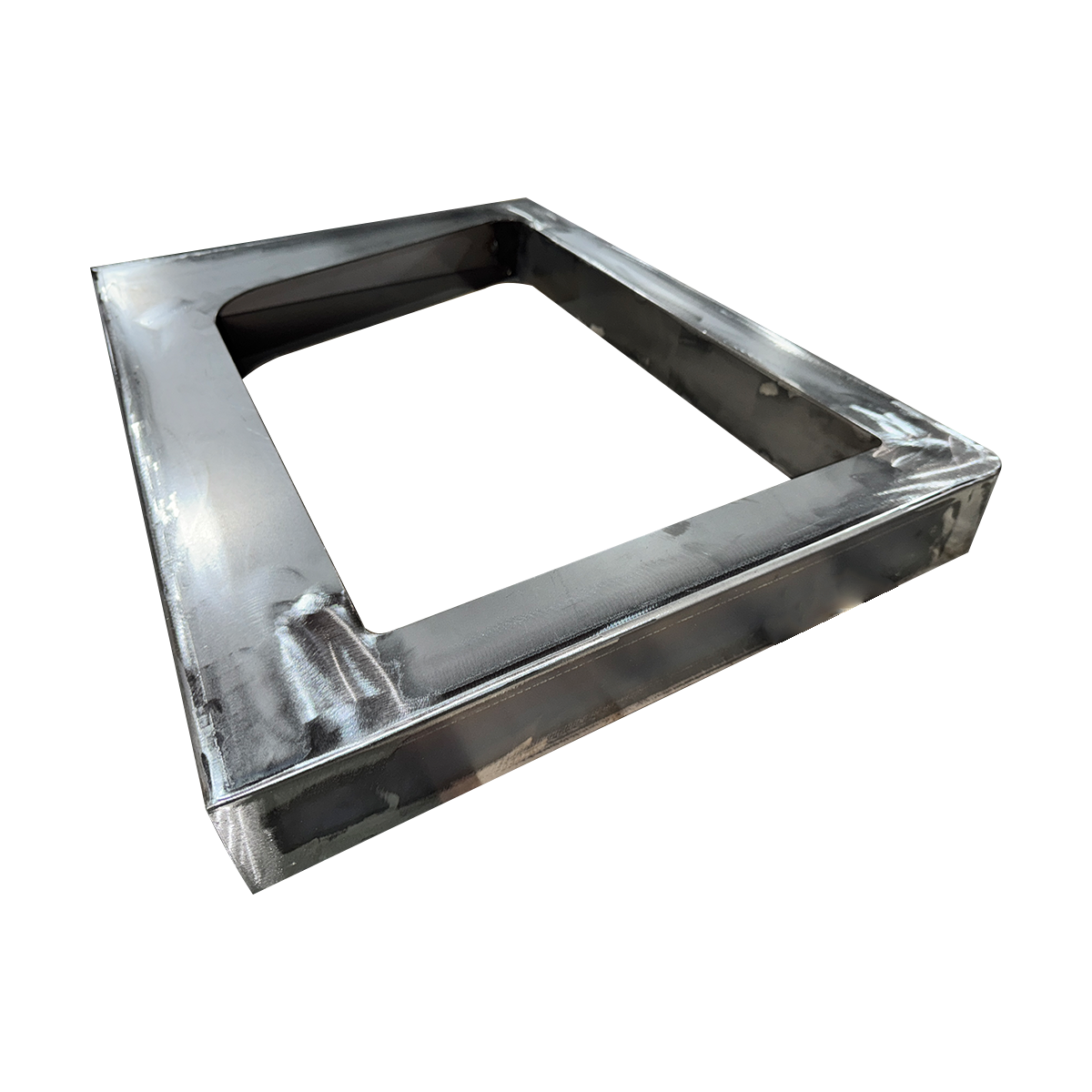

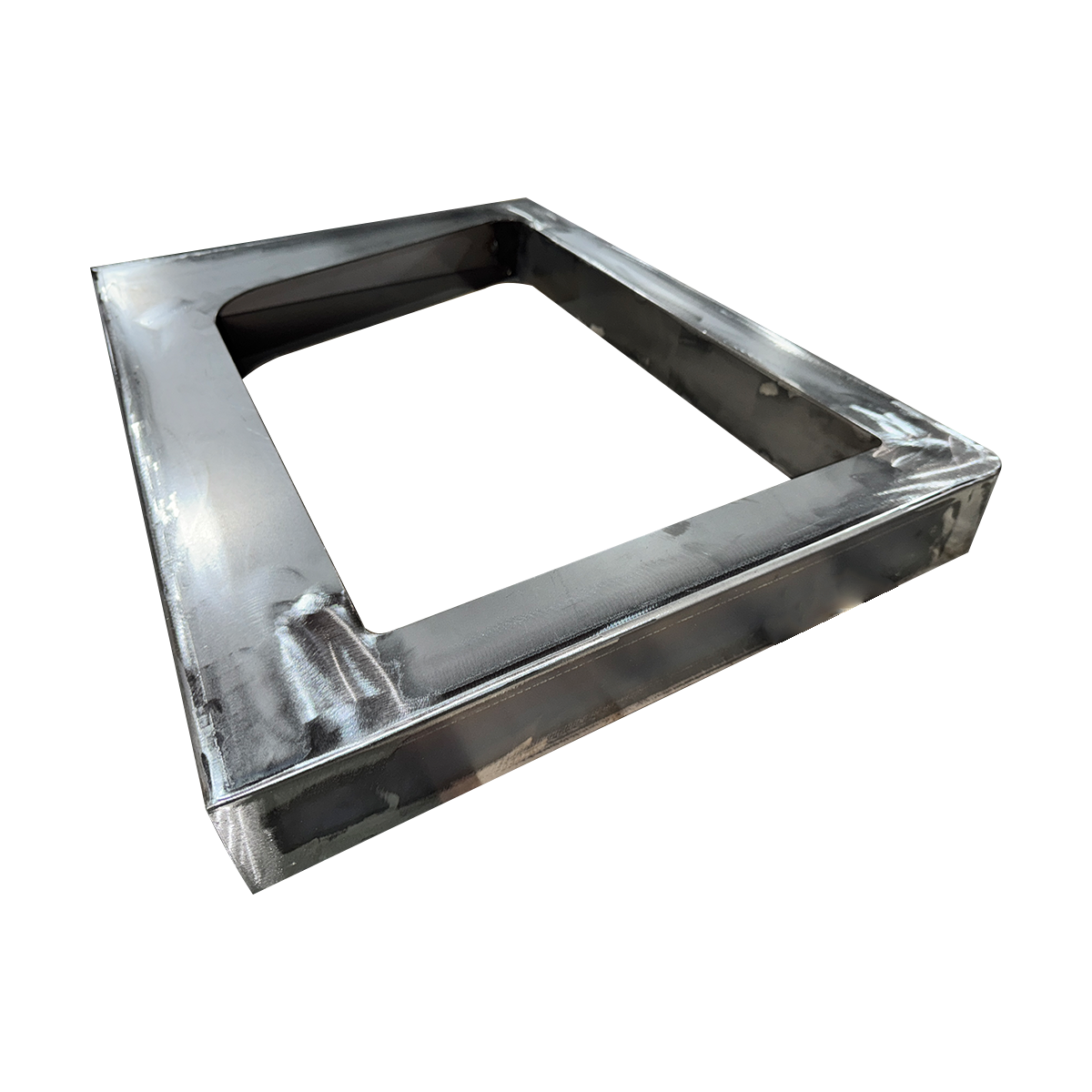

Material Versatility: Stainless steel, aluminum, and galvanized steel are commonly used, ensuring corrosion resistance and structural integrity. For example, low cost jumbo chassis for industrial equipment often rely on galvanized steel to balance cost and durability.

Precision Manufacturing: Advanced techniques like laser cutting and CNC bending enable tolerances as tight as ±0.1mm, crucial for components like car shelf brackets that require seamless integration into vehicle designs.

Scalability: Whether producing a single prototype or bulk orders for metal chassis wholesale, modern fabrication facilities can adapt to diverse requirements, making them ideal for businesses looking to buy jumbo chassis in large quantities.

Leading metal chassis factories, particularly in hubs like China, have emerged as global leaders in combining technology with cost-effective production. Here’s how they address industry needs:buy jumbo chassisbuy jumbo chassisbuy jumbo chassisbuy jumbo chassisbuy jumbo chassisbuy jumbo chassisbuy jumbo chassisbuy jumbo chassisbuy jumbo chassisbuy jumbo chassissupply metal chassis

Advanced Production Lines: Equipped with robotic welding systems and automated bending machines, these factories can manufacture metal chassis with consistent quality while reducing labor costs. For instance, a low cost jumbo chassis for logistics equipment might undergo 10+ automated checks to ensure load-bearing capacity.

Customization Capabilities: Whether clients need a standard metal chassis or a specialized design for renewable energy systems, factories offer end-to-end customization. This includes integrating features like heat dissipation slots or mounting points for car shelf brackets.

Quality Control: Stringent testing, such as salt spray tests for corrosion resistance and load tests for structural strength, ensures that products like jumbo chassis meet international standards (e.g., ISO 9001).

In the automotive sector, car shelf brackets must withstand vibration, weight loads, and environmental stress. Sheet metal fabrication solves this by:

Using high-strength aluminum alloys to reduce weight without compromising stability.

Incorporating anti-rust coatings like electrophoretic painting for long-term durability.

Ensuring precise hole positioning for easy installation in vehicle frames.

For industries requiring heavy-duty solutions, low cost jumbo chassis are essential for:

Industrial machinery: Supporting motors and controllers in manufacturing plants.

Data center racks: Providing stable foundations for server arrays.

Renewable energy systems: Housing batteries and inverters in solar or wind setups.

Factories achieve cost efficiency through bulk material purchasing, optimized production flows, and modular designs that minimize waste.

For businesses looking to supply metal chassis or buy jumbo chassis, partnering with a reliable factory involves:

Technical Expertise: Choose a metal chassis factory that offers design consultation, such as 3D modeling to visualize the final product.

Cost Transparency: Factories specializing in low cost jumbo chassis should provide clear quotes that detail material, labor, and finishing costs.

Lead Time Assurance: Efficient supply chains ensure timely delivery, crucial for industries like automotive manufacturing where production schedules are tight.

After-Sales Support: Look for providers that offer warranty services and replacement parts for components like car shelf brackets.

A leading logistics company recently partnered with a Chinese metal chassis factory to develop a low cost jumbo chassis for their automated sorting systems. The solution involved:

A galvanized steel frame capable of supporting 500kg+ loads.

Pre-drilled slots for easy integration with conveyor belts.

A powder-coated finish to resist dust and moisture in warehouse environments.

The result: a 30% cost reduction compared to traditional steel chassis, with a lifespan extended by 5+ years due to superior corrosion resistance.

From car shelf brackets that enhance vehicle safety to low cost jumbo chassis that power industrial innovation, sheet metal fabrication continues to be the backbone of modern manufacturing. For businesses aiming to supply metal chassis or buy jumbo chassis, partnering with an advanced metal chassis factory ensures access to precision, durability, and cost efficiency. As industries worldwide demand more reliable, customizable components, the art of sheet metal fabrication will only grow in importance—driving progress one bend, cut, and weld at a time.