Our company has recently produced a batch of customized metal shells, which have received unanimous praise from customers. Choosing our products has many advantages

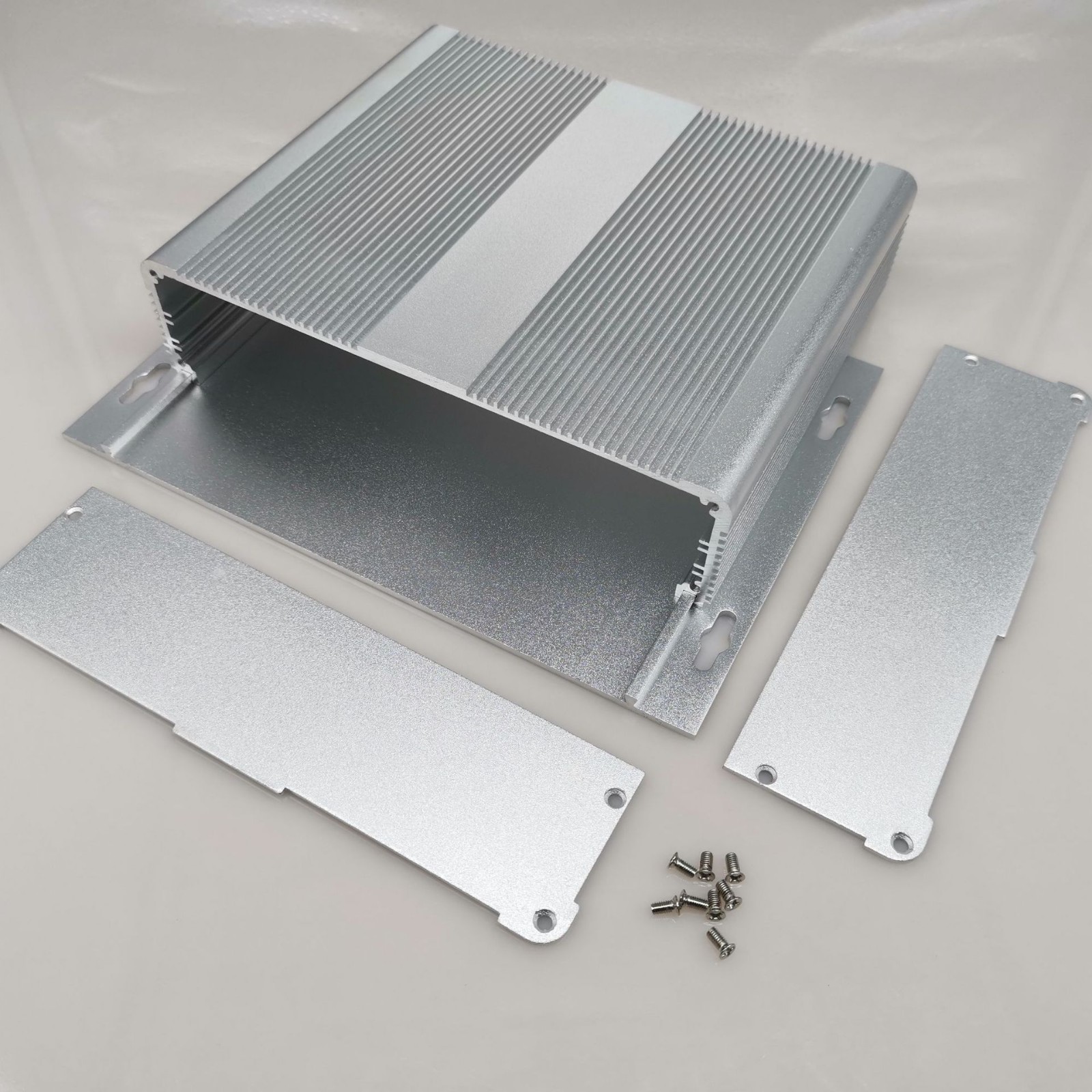

1、 This metal shell product, newly produced by a sheet metal company, has a unique appearance and design. Its overall design is simple and smooth, with rigid yet elegant lines. The surface of the shell has been finely processed, giving it a delicate texture that can be as smooth as a mirror, giving people a visual impact full of modernity and technology; It can also be a frosted texture with unique textures, which increases the friction during grip and gives the product a low-key and restrained industrial style.

From a design perspective, it fully considers the adaptability of different devices. Whether it's compact small electronic devices or larger industrial instruments, this metal casing can perfectly fit. Its structural design is reasonable, with tight and natural connections between various components, without any abrupt splicing marks. The rounded edges and corners are treated to avoid potential safety hazards caused by sharp edges, while also enhancing the overall aesthetics of the product to a certain extent.

2、 Material and Quality: Sheet metal companies strive for excellence in material selection. We use high-quality metal materials, which have the characteristics of high strength and toughness. This enables the metal casing to effectively protect internal equipment from damage when subjected to external pressure and impact forces. At the same time, the corrosion resistance of this metal is also quite excellent, and it can maintain the integrity and aesthetics of the shell for a long time, whether in humid environments or special occasions where it may come into contact with corrosive substances.

In terms of production technology, sheet metal companies have utilized advanced techniques. Each shell undergoes precise cutting, bending, welding, and other processes. The cutting process ensures the accuracy of the dimensions, with errors controlled within a very small range, thus ensuring a perfect fit between the outer shell and the internal equipment. The bending process enables the shape of the shell to be accurately formed according to design requirements, while the welding joints are firm and reliable. After strict quality inspection, it is ensured that there will be no quality problems such as cracks or virtual welding.

3、 The metal shell product has many highlights in terms of functionality and application. Firstly, it has excellent heat dissipation performance. The metal material itself has good thermal conductivity, coupled with carefully designed heat dissipation holes or channels on the shell, which can quickly dissipate the heat generated by internal equipment, thereby ensuring the stability of the equipment during long-term operation. This is a very important feature for some high-performance, high-power devices. In terms of electromagnetic shielding, this metal casing also performs well. It can effectively block external electromagnetic interference and prevent the leakage of electromagnetic signals generated by internal devices, thereby ensuring the normal operation of the equipment and avoiding interference with other surrounding devices.

Its application range is very wide. In the field of consumer electronics, such as smartphones, tablets, laptops and other devices, it can be used as a high-end customized shell to enhance the overall quality and protective capabilities of the product. In the industrial field, various instruments, controllers, servers, and other equipment can also benefit from the high-strength protection and excellent performance of this metal casing. In the field of automotive electronics, it can also be used as the outer shell of automotive control systems, sensors, and other equipment to adapt to complex automotive usage environments.