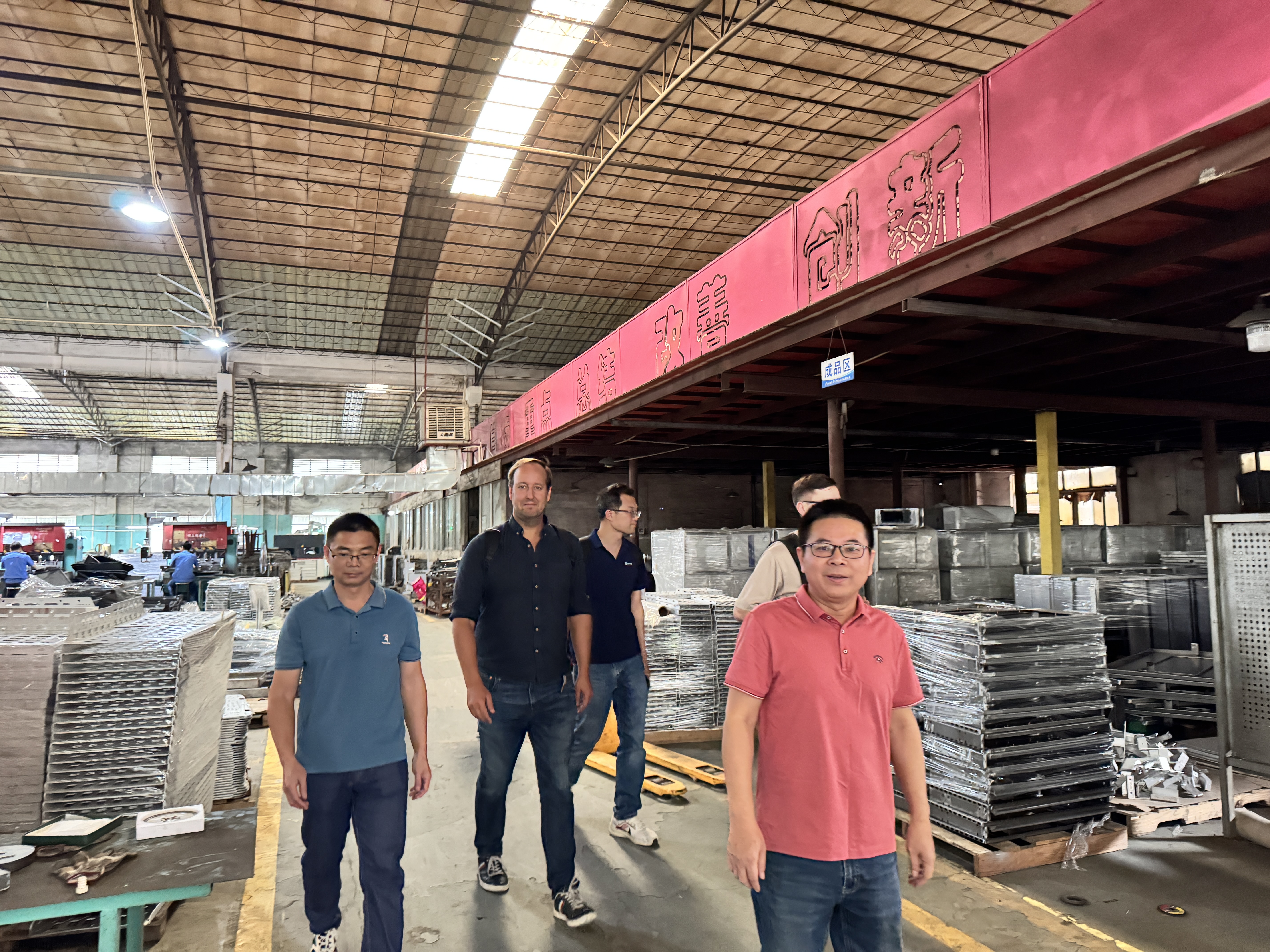

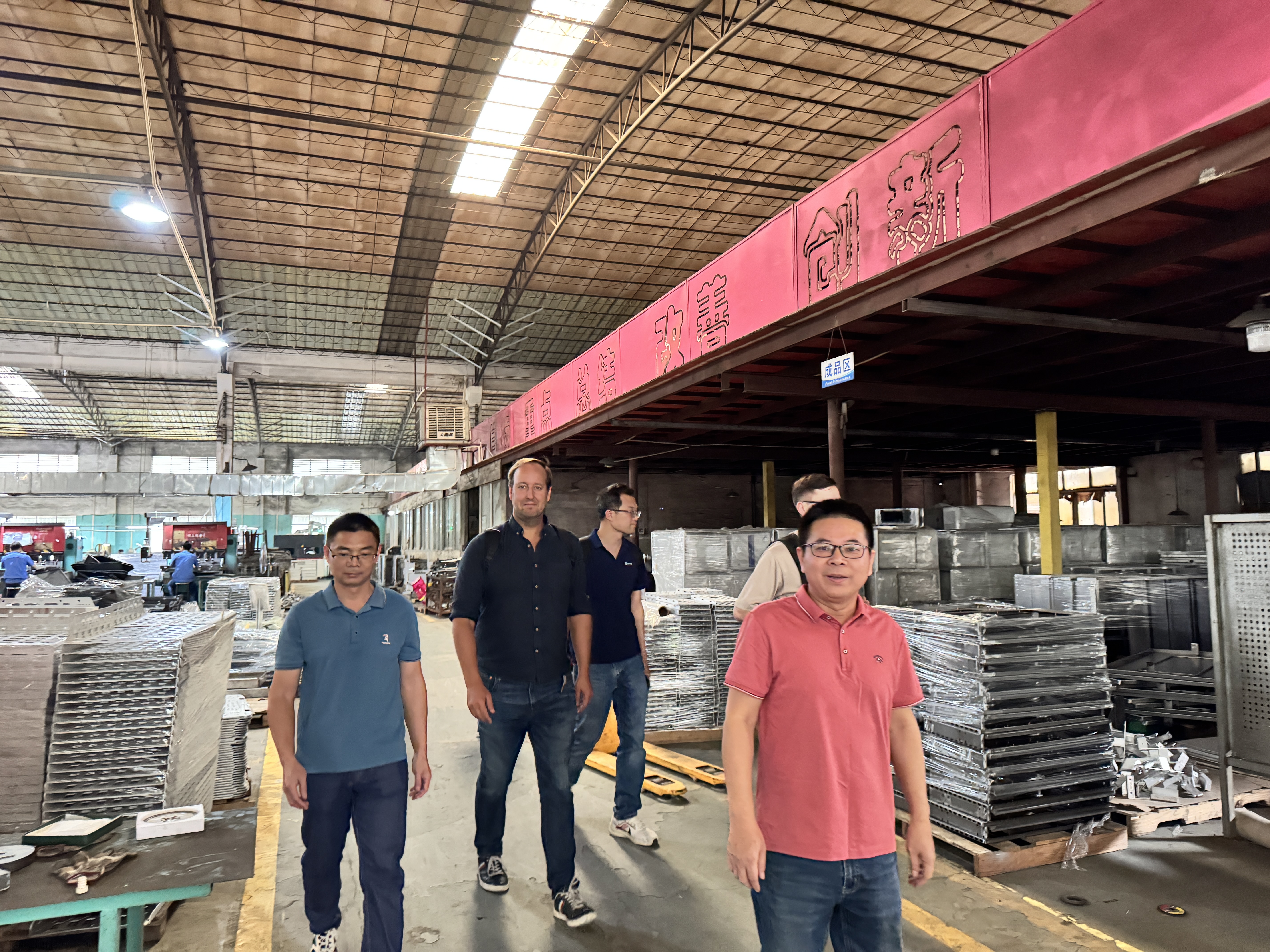

In the context of close collaboration in the global manufacturing industry, WongSam Sheet Metal Technology Co., Ltd. has attracted the attention of numerous international clients with its outstanding performance in sheet metal custom processing. Recently, an important international client delegation visited the company. Through on - site inspections and in - depth exchanges, they highly appraised the company's comprehensive strength, reaching a consensus on future cooperation and laying a solid foundation for jointly exploring the market.Metal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal CabinetsMetal Cabinets

On the first day of the inspection, accompanied by the company's senior management and technical experts, the international client delegation entered the spacious, bright, and orderly production workshop. As soon as they stepped in, the 30,000 - watt high - power laser cutting machine immediately caught the clients' attention. It was cutting stainless - steel sheets of various thicknesses at an extremely high speed and precision. The dazzling laser beam moved precisely along the preset path, instantly separating the sheets. The cut edges were smooth and flat without obvious burrs, demonstrating its powerful processing capabilities and high - precision features. The clients picked up the cut samples for a closer look and spoke highly of their quality.Metal Storage CabinetsMetal Storage CabinetsMetal Storage CabinetsMetal Storage CabinetsMetal Storage CabinetsMetal Storage CabinetsMetal Storage CabinetsMetal Storage Cabinets

In the area of the leveling machine, sheets with slight wrinkles and unevenness became perfectly flat after going through multiple processing procedures of the equipment. The technicians explained in detail to the clients that the leveling machine adopted advanced roller - pressing technology, which could effectively eliminate the stress and deformation generated during the production and transportation of the sheets, ensuring the accuracy and quality of subsequent processing and laying a solid foundation for creating high - quality sheet metal products. Through on - site observation and the technicians' explanations, the clients fully recognized the company's rigorous attitude in basic process control.Sheet Metal CustomizationSheet Metal CustomizationSheet Metal CustomizationSheet Metal CustomizationSheet Metal CustomizationMetal Storage CabinetsMetal Storage CabinetsMetal Storage CabinetsMetal Storage CabinetsMetal Storage CabinetsMetal Storage CabinetsMetal Storage CabinetsMetal Storage CabinetsMetal Storage Cabinets

In the workshop, several bending machines and CNC punching machines were operating in coordination. Under the precise control of the numerical control system, the bending machines folded the sheets into the set angles and shapes. Each bending action was stable and accurate, meeting the requirements of different products for complex structures. The CNC punching machines quickly and efficiently punched holes of various specifications and shapes in the sheets. Whether they were round, square, or irregular holes, they were all perfectly formed, providing key support for the assembly and functionality of products such as metal cabinets and agricultural accessories. The clients showed great interest in the efficient operation and advanced performance of these devices, frequently asking questions about equipment parameters, processing efficiency, and applicable materials, to which the technicians gave detailed answers.Agricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural Accessories

During this inspection, the clients mainly focused on the application of sheet metal customization in two key areas: agricultural accessories and metal cabinets. In the agricultural accessories display area, the company's technical team introduced a series of products customized for agricultural machinery. Taking sheet metal feed troughs as an example, aiming at different breeding scenarios and animal habits, the company created rectangular stainless - steel feed troughs of various specifications and structures through exquisite bending and edge - folding techniques. These feed troughs not only had excellent corrosion resistance and strength, enabling them to adapt to the humid and acidic - alkaline environment of farms, but also took into full account the convenience and comfort of animals during feeding in their design. For example, the reasonable depth and inclination angle of the troughs effectively reduced feed waste and improved breeding efficiency. The clients highly praised these design details and craftsmanship, believing that they fully reflected the company's professional accumulation and innovative capabilities in the agricultural field.Sheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal PartsSheet Metal Parts

Regarding metal cabinets, the technicians started by introducing the design planning in the early project stage. The company has a professional design team that can use advanced 3D design software to conduct precise dimension planning and structural design according to the clients' equipment installation requirements, usage environment, and functional needs. During the production process, laser cutting technology ensured that the holes in each component of the cabinet were precisely positioned and of consistent size, facilitating equipment installation. The bending process formed a sturdy and stable framework, guaranteeing the overall strength and protective performance of the cabinet. Meanwhile, the company can also perform various surface treatments on the cabinets, such as spraying and electroplating, at the clients' request, enhancing the cabinets' aesthetic appeal and anti - rust ability. After listening to the introduction, the clients fully affirmed the company's full - process service capabilities in metal cabinet customization and had in - depth discussions with the technical team about their own project requirements.

At the conclusion of the inspection, the client representative delivered a speech during the summary meeting: "This inspection has left an extremely deep impression on us. From advanced production equipment and exquisite processing techniques to professional customized solutions, as well as a complete quality and delivery assurance system, every aspect demonstrates your company's profound strength and outstanding pursuit in the field of sheet metal custom processing. Whether it is the customization of metal processed parts or the large - scale production of metal storage cabinets, we see broad space for cooperation. We look forward to establishing a long - term and stable cooperative relationship with WongSam, working together to create more high - quality projects and achieving mutual benefit and win - win results."

The person in charge of the company expressed heartfelt gratitude for the clients' recognition and stated, "Client satisfaction is our greatest driving force. In the future, WongSam will continue to adhere to the concept of 'technological innovation, quality first, and considerate service,' continuously increase investment in equipment upgrading, technological research and development, and talent cultivation, and continuously enhance the company's core competitiveness. We are willing to work with global clients to deeply cultivate the field of sheet metal custom processing, jointly explore the market, and create a brighter future."

This international client inspection activity was not only a comprehensive test of WongSam Sheet Metal Technology's comprehensive strength but also an important opportunity for the company to expand into the international market and deepen international cooperation. It is believed that with the joint efforts of both sides, fruitful cooperation results will surely be achieved in the field of sheet metal customization in the future, contributing to the development of the global manufacturing industry.