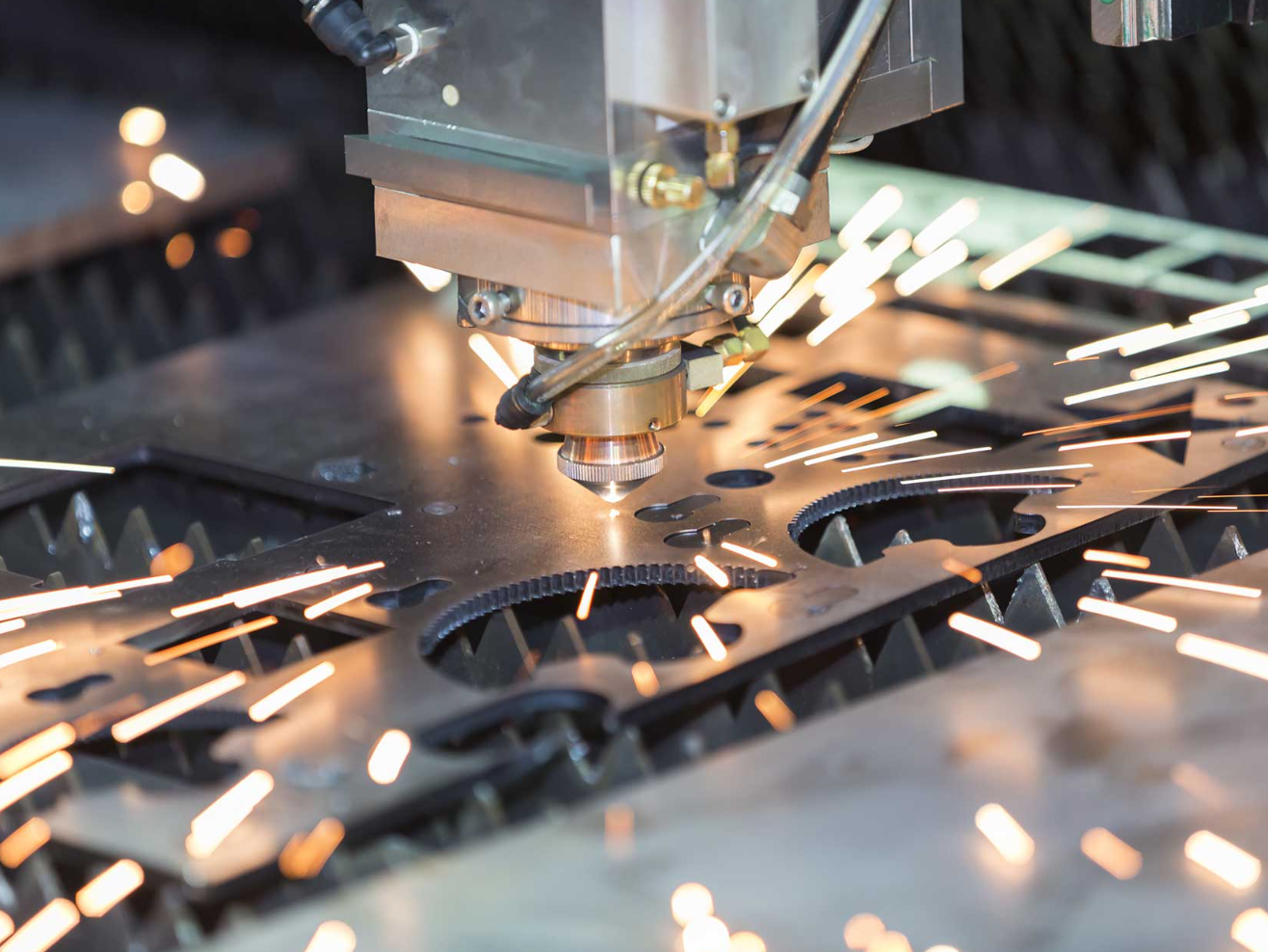

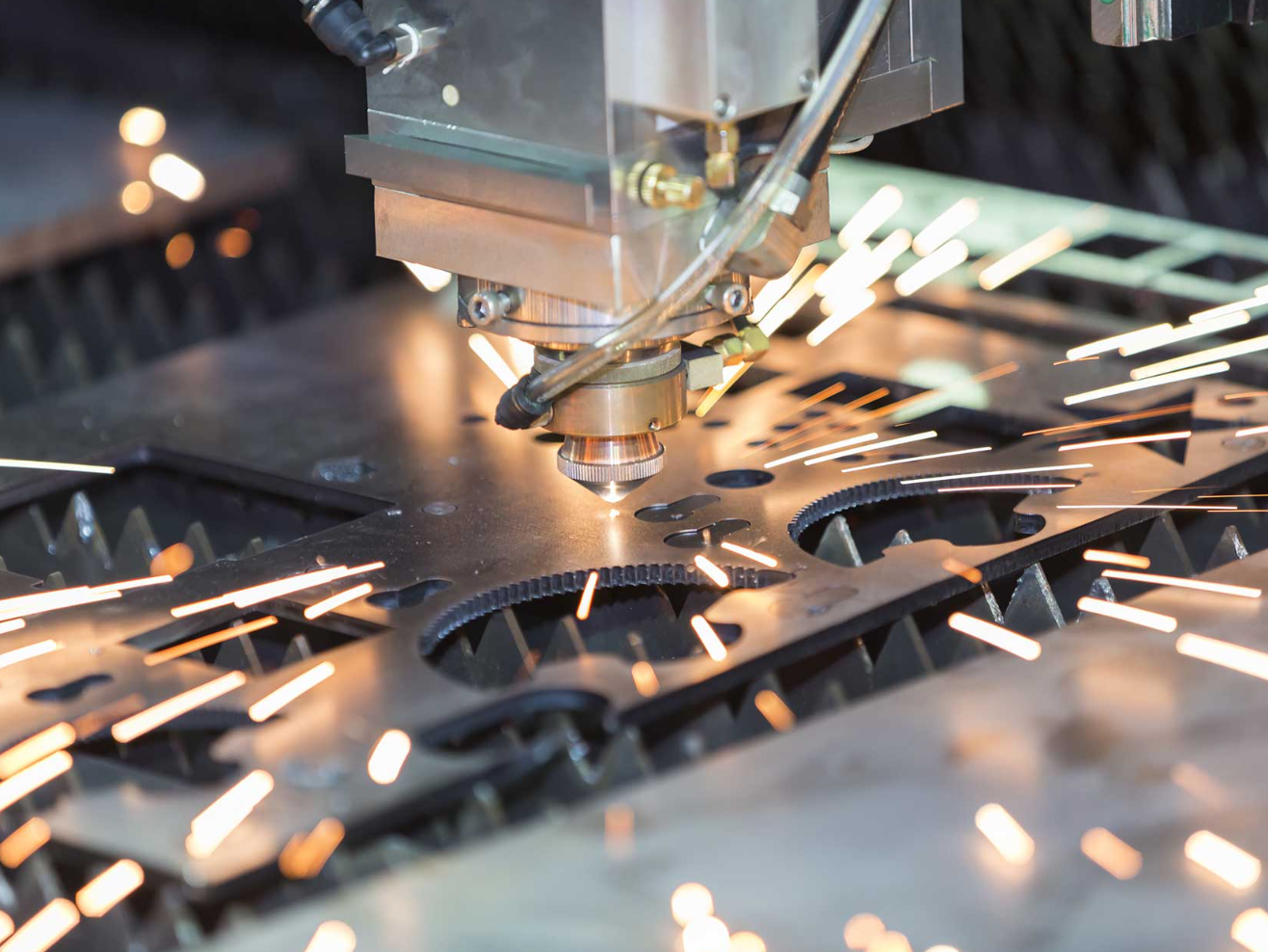

In modern manufacturing, sheet metal processing is a cornerstone, and laser cutting has become transformative. High-power laser cutting stands out in agricultural machinery, crucial for crafting sheet metal enclosures and sheet metal accessories in breeding equipment and livestock equipment. From feeding system frames to environmental control components, it reshapes production, driving efficiency and innovation.

As livestock farming automates, demand for durable, well-fitted equipment grows. Traditional methods like plasma cutting fall short in quality, speed, or material range. High-power laser cutting handles thick materials, creates intricate designs with minimal waste, and maintains precision in large runs, filling this gap.

I. Core Advantages: Speed and Precision

High-power laser cutting (≥3000W) outperforms conventional methods in livestock equipment production, enhancing efficiency and quality.farming equipmentfarming equipmentfarming equipmentfarming equipmentfarming equipmentfarming equipment

1. Thick Plate Efficiency

Farming equipment needs thick steel (6-12mm) for strength. A 2000W laser cuts 10mm steel at 1.5m/min, slowing production. A 6000W system reaches over 4m/min, tripling efficiency. For 1000 thick-plate bases, production drops from 5 to 3 days, a 40% reduction. Annual runs of 50,000+ units save hundreds of hours, aiding assembly and R&D.livestock equipmentlivestock equipmentlivestock equipmentlivestock equipmentlivestock equipmentlifarming equipmentfarming equipment

2. Precision and Edge Quality

High energy density minimizes heat-affected zones (HAZ), reducing warping. Critical for sheet metal enclosures with electronics: sensor holes have ±0.05mm tolerance, edges (Ra ≤1.6μm) need no grinding. Smooth edges ensure tight seals in intelligent livestock equipment, preventing seal wear from burrs, which cuts maintenance and extends lifespan.sheet metal processingsheet metal processingsheet metal processingsheet metal processingsheet metal processingsheet metal processing

3. Material Versatility

It processes diverse materials for harsh farm conditions:sheet metal processingsheet metal processingsheet metal processing

II. Key Applications in Livestock Equipment

High-power laser cutting solves unique manufacturing challenges across component types.

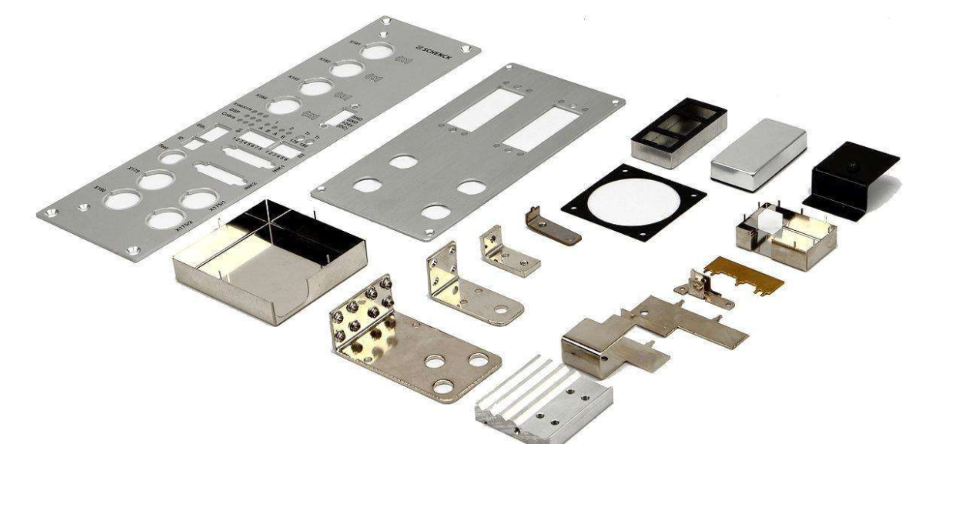

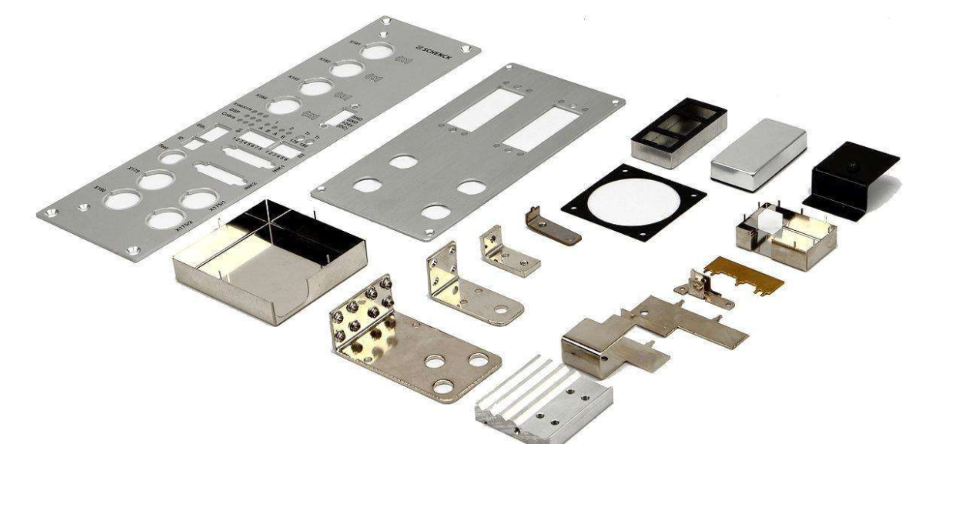

1. Complex Enclosures

Intelligent feeding systems need enclosures with irregular vents, windows, and wiring holes. Stamping requires costly, inflexible dies. Laser cutting uses CAD for "mold-free" production, enabling quick design changes. A 1.5mm galvanized steel control cabinet with 200 vents, a window, and 12 holes takes just 2 minutes to cut—no deformation, unlike stamping.farming equipmentfarming equipmentfarming equipmentfarming equipmentfarming equipmentsheet metal accessories

2. Batch Accessories

Small parts like hoppers and brackets need consistency. Advanced nesting software fits 32 feed distributor side plates on a 1220×2440mm sheet (15% better than manual), saving 80 tons of steel yearly for 100,000 sets. ≤0.03mm repeat error ensures parts fit, reducing assembly time and wear.

3. Thick Structural Parts

8mm+ steel brackets for manure systems need precision. Plasma cutting leaves dross and large HAZ, requiring grinding. A 6000W laser makes clean cuts with ±0.5mm accuracy (vs. ±2mm with plasma), boosting frame stability by 30%, extending equipment life.sheet metal accessoriessheet metal accessoriessheet metal accessoriessheet metal accessories

III. Technical and Cost Benefits

Advanced tech ensures performance, with long-term savings outweighing initial costs.

1. Intelligent Controls

Real-time sensors adjust speed, power, and gas pressure. Dynamic focusing maintains ≤0.2mm spot size on curved equipment enclosure edges. Vision positioning corrects sheet misalignment, cutting setup time and waste.sheet metal accessoriessheet metal accessoriessheet metal accessories

2. Cost Savings

Payback: 2-3 years for moderate production volumes.

IV. Future Trends

Emerging tech will enhance its role in livestock equipment evolution.

High-power laser cutting revolutionizes breeding equipment production, offering speed, precision, and versatility. It’s indispensable for modern manufacturers, set to drive innovation as farming advances—from small parts to large structures, shaping agricultural machinery’s future.