Today, the factory's production processes progressed in an orderly manner, successfully completing multiple processing tasks. The specific work is as follows:Sheet Metal Processing FactorySheet Metal Processing FactorySheet Metal Processing FactorySheet Metal Processing FactorySheet Metal Processing shee metal factoryshee metal factoryshee metal factoryshee metal factorySheet Metal Parts

1. Laser Tube Cutting OperationThe sheet metal workshop used a laser tube cutting machine to precisely cut a batch of stainless steel tubes. By controlling the cutting angle and length through preset programs, the flatness and dimensional accuracy of the tube ends were effectively ensured, providing qualified components for subsequent ventilation duct assembly.Sheet Metal PartsSheet Metal Parts

2. Welding Production of Ventilation Duct Protective GrillsThe welding team completed the welding task for the protective grills for the ventilation ducts. Using CO2 gas shielded welding technology ensured even and firm welds, a flat grid without deformation, and that the overall structural stability and ventilation performance of the product met design requirements.Sheet Metal PartsSheet Metal Partshee metal factoryshee metal factoryshee metal factoryshee metal factoryshee meProcessing factoryProcessing factoryProcessing factoryProcessing factoSheet Metal PartsSheet Metal Partsry

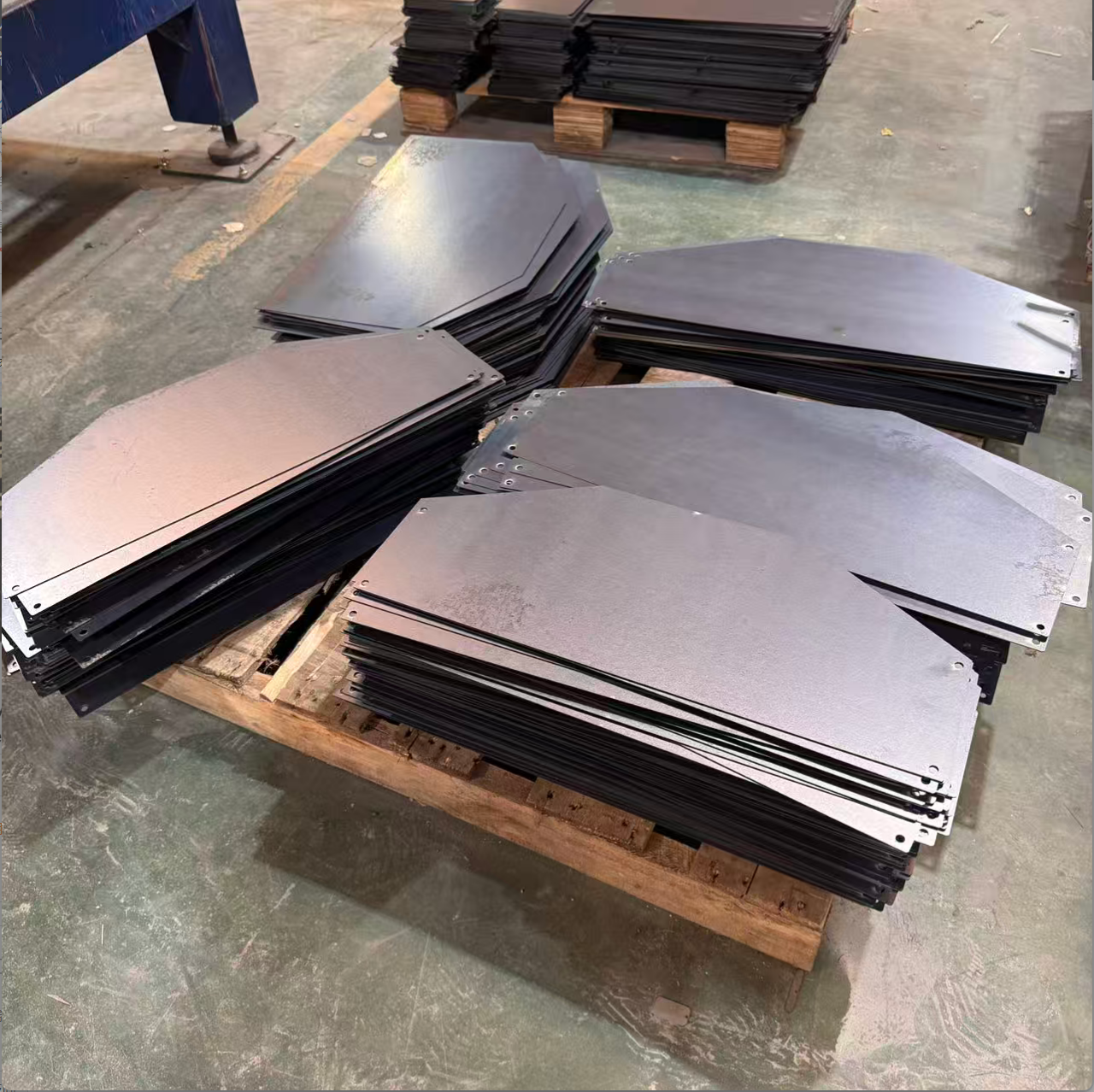

3. Customer Product Laser Sheet Cutting OperationIn the laser cutting area, cold-rolled steel sheets of various specifications were laser cut according to customer orders. By optimizing the layout plan, material utilization was improved, with smooth and burr-free cutting edges, laying a solid foundation for the next process.Auto partsAuto partsAuto partsAuto partsAuto partsAuto partsAuto partsAuto paAuto partsAuto partsrAuto partsAuto partstsAuto parts

4. Preliminary Product Grinding and PolishingThe surface treatment workshop polished and ground the assembled sheet metal products. By combining angle grinders and manual polishing, weld slag and surface scratches were removed, bringing the product appearance up to customer acceptance standards.

Today's Work Highlights

- The laser tube cutting operation reduced material waste by 5%

- The welding pass rate of ventilation duct protective grills reached 99.2%

- Laser sheet cutting efficiency increased by 20%

compared to traditional processesAll workshops worked closely together, effectively improving production efficiency while ensuring quality. The company will continue to maintain a rigorous work attitude to provide customers with high-quality sheet metal processing services.