What are the advantages of laser cutting and why do we choose laser cutting to produce products?

1、 High precision

Laser cutting has extremely high precision. Laser beams can focus on very small light spots, achieving cutting accuracy at the millimeter or even micrometer level. This makes it excellent in processing precision components, such as in the field of electronic device manufacturing. For cutting small circuit boards and chip components, laser cutting can ensure smooth and neat cutting edges, minimize errors, and ensure the performance and stability of electronic components.

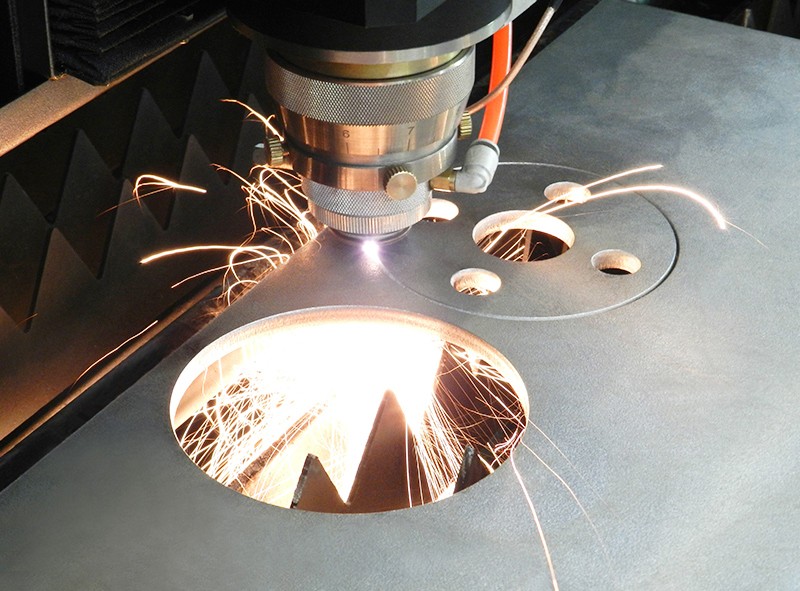

2、 High cutting quality

(1)The cutting surface produced by laser cutting is smooth and free of burrs. Compared with traditional cutting methods, laser cutting can directly meet the needs of many application scenarios without the need for secondary polishing or other precision processing on the metal surface after cutting metal materials.

(2). The heat affected zone is small. Although heat is also generated during the laser cutting process, due to the high concentration of laser energy and fast heat dissipation, the heat affected area around the cutting material is very small. This is crucial for materials that are sensitive to heat, such as special alloy materials or plastic products, to avoid the problem of material performance changes caused by thermal effects.

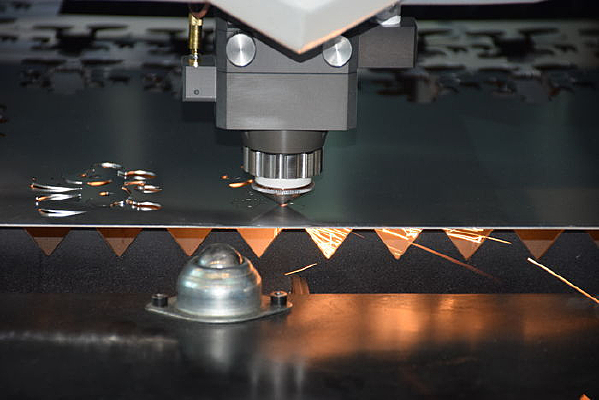

3、 Strong flexibility

(1). Laser cutting can cut various types of materials. Laser cutting can effectively perform cutting operations on both metallic materials (such as steel, aluminum, copper, etc.) and non-metallic materials (such as wood, plastic, ceramics, etc.). This wide applicability enables laser cutting to play a role in many different industrial fields.

(2). It can easily achieve cutting of complex shapes. With the support of computer-aided design (CAD) software, laser cutting equipment can accurately cut according to preset complex patterns, such as cutting some parts with special shapes in automobile manufacturing, or cutting creative shapes in the field of artistic creation.

4、 Fast speed

When cutting thin materials, laser cutting speed is quite fast. It can complete a large number of cutting tasks in a short period of time, improving production efficiency. With the continuous development of laser technology, high-power laser cutting equipment is constantly emerging. For some thicker materials, the cutting speed is also constantly improving, which can effectively shorten the production cycle in large-scale production.

5、 Non contact cutting

Laser cutting is a non-contact processing method. There is no mechanical contact between the laser beam and the material being cut, so it will not cause mechanical stress on the material. This is very advantageous when cutting fragile or poorly rigid materials, reducing the risk of material breakage or deformation during the cutting process.

In summary, this is why we choose laser cutting.

Wongsam Sheet Metal Technology Co., Ltd. has always used the most advanced technology to provide every customer with the highest quality products, so that every customer can choose us with confidence!