A New Paradigm for Efficient Animal Husbandry: Sheet Metal Feed Troughs Empower the Intelligent Upgrading of Large - Scale Ranches

In the wave of large - scale development of the livestock industry, the upgrading of breeding equipment is directly related to breeding efficiency and cost control. To enhance breeding efficiency, a large - scale modern ranch introduced customized sheet metal feed troughs from our company. Through advanced sheet metal technology and intelligent design, it successfully created an efficient breeding solution, achieving a dual breakthrough in cost reduction, efficiency improvement, and precise feeding.Animal Feeding EquipmentAnimal Feeding EquipmentAnimal Feeding EquipmentAnimal Feeding EquipmentAnimal Feeding EquipmentAnimal Feeding EquipmentAnimal Feeding EquipmentAnimal Feeding Equipment

Problem Analysis: The Efficiency Bottlenecks of Traditional Breeding Equipment

Customized Solutions: Sheet Metal Technology Solves Breeding Problems

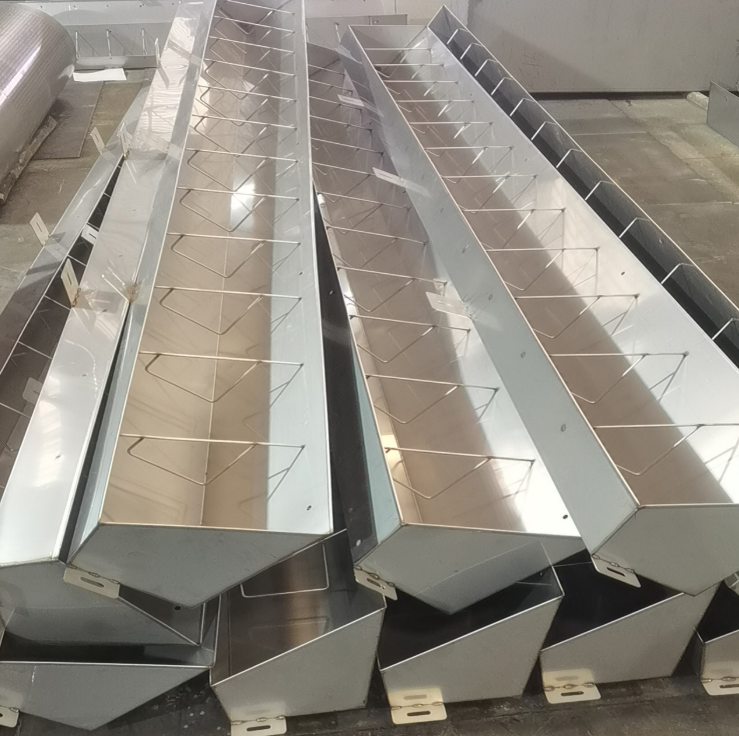

Based on the ranch's needs, our company customized the feed trough solution with sheet metal technology at its core, focusing on materials, structure, and functionality. For materials, food - grade 304 stainless steel sheets were selected, which combined high strength, corrosion resistance, and non - toxicity to ensure feed safety. In structural design, laser cutting technology was used for precise shaping, and a trapezoidal trough body was formed through CNC bending. The inclination angle was optimized by fluid mechanics, allowing the feed to slide naturally to the feeding area, reducing the residue rate by 90%. Meanwhile, drainage holes were reserved at the bottom of the trough to prevent feed from mildewing. To meet the ranch's automated feeding requirements, the sheet metal feed troughs were also equipped with interfaces for intelligent sensors, enabling seamless connection to the ranch's IoT system, which could monitor feed levels in real - time and automatically refill.

Sheet Metal TroughSheet Metal TroughSheet Metal TroughSheet Metal TroughSheet Metal TroughSheet Metal TroughSheet Metal TroughSheet Metal TroughSheet Metal TroughSheet Metal TroughAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural Accessories

Production Challenges: A Full - Process Technology Ensures Quality

During production, our company leveraged its sheet metal processing technology. First, high - precision laser cutting machines were used to cut stainless steel sheets into standard components, with an error control of ±0.1mm. Subsequently, CNC bending machines bent the components into shape with an accuracy of 0.1°, ensuring the stability of the trough structure. In the welding process, argon arc welding technology was employed to achieve seamless welding, ensuring both tightness and aesthetic appeal. Finally, surface wire drawing treatment was carried out to enhance the wear resistance and cleaning convenience of the trough. Each batch of products underwent salt spray tests, load - bearing tests, and food safety inspections to ensure compliance with high industry standards.

Agricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgriculturalLivestock Feeding AccessoriesLivestock Feeding Accessories

AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgricultural AccessoriesAgriculturalLivestock Feeding AccessoriesLivestock Feeding Accessories

AccessoriesLivestock Feeding AccessoriesLivestock Feeding AccessoriesLivestock Feeding AccessoriesLivestock Feeding AccessoriesLivestock Feeding Accessories