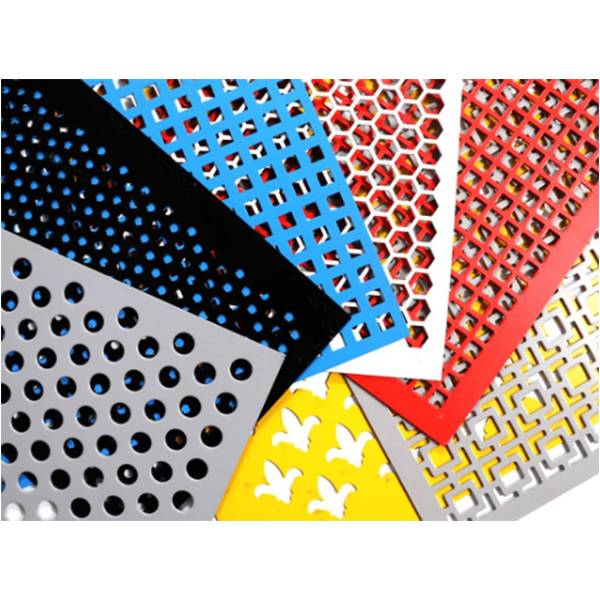

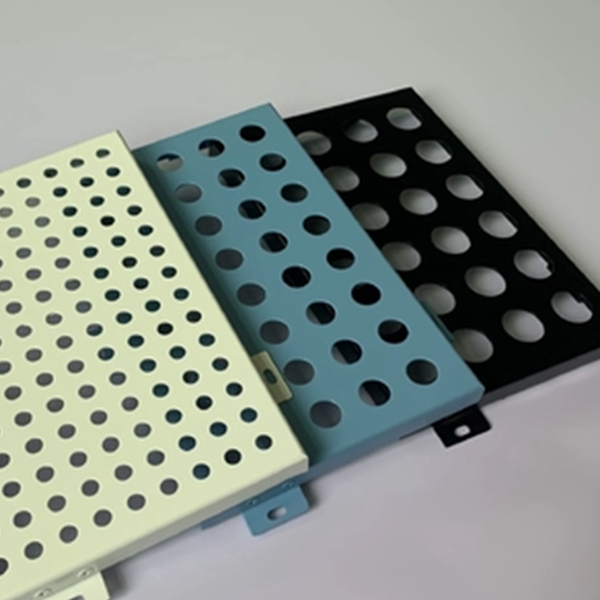

Black White Powder Coated Perforated Metal Sheet

In the construction and decoration industry, black and white powder coated perforated metal sheets are widely used materials. They are favored for their unique appearance and versatility. Both black and white perforated metal sheets are common choices, and perforated metal sheets treated with powder coating are more durable and beautiful.

Black perforated metal sheets are specially treated metal sheets with tiny holes on the surface, which can enhance the ventilation and light transmission of the material. The black appearance gives people a stable and atmospheric feeling, and is often used in modern style buildings and decorations. This material is suitable for various places, such as building exterior walls, ceilings, partitions, etc., which can not only play a decorative role, but also provide a certain degree of privacy protection.

In contrast, white perforated metal sheets present a refreshing and bright appearance and are often used in environments that need to increase brightness, such as medical institutions, laboratories, etc. White perforated metal sheets not only have the functions of ventilation and light transmission, but also make the indoor space more open and bright, creating a comfortable working or living environment.

Perforated metal sheets treated with powder coating have higher weather resistance and corrosion resistance, can resist harsh environmental influences, and extend the service life of the material. Powder coating can make black and white perforated metal sheets more durable, increase their stain resistance, and make cleaning more convenient.

In general, black and white powder coated perforated metal sheets not only have decorative effects, but also have certain functionality and are suitable for a variety of different occasions. Their appearance enriches the choice of building and decoration materials, creating a more beautiful and practical space environment for people.

Sheet metal parts are found almost everywhere and Wongsam Sheet Metal Technology Co., Ltd ( Wongsam ) can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes. We have an ultra low MOQ (minimum order quantity) of one unit and offer lots of manufacturing options for low/mid volumes.

How It Works – Sheet metal encompasses a wide range of processes to manipulate and shape sheets of metal into the required form or geometry. Wongsam use bending, laser cutting, punches, welding and other processes to manufacture your sheet metal parts and prototypes.

Contact us today to find out more about our sheet metal production services.

Optional Materials

Brass, Aluminum, Stainless steel , and Zinc etc.

Customized Thickness

The thickness of sheet metal can be done as per client's request. Thickness: 0.6-60mm available

Low material waste

Can cost-effectively scale to production volumes

Multiple finishing options like anodizing and powder coating

Sheet Metal Applications

Sheet metal is a versatile manufacturing process for a range of metal components. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Common sheet metal parts include:

Sheet Metal Fabrication, Parts

Metal Cabinets, Box, Enclosure

Metal Racks, Shelves, Bracket

Metal Veneer, Panel, Facade

Car Shelf Bracket

Metal Chassis, Frame

Turned Parts

Appliances